How to choose The Best Returns management software for your ecommerce business

What does in transit mean and how long does it take? Read this article to find out & see how to answer your customers’ burning questions.

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

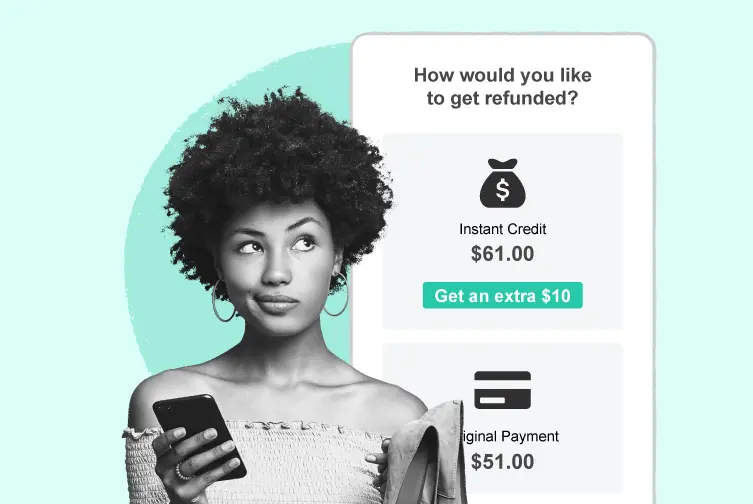

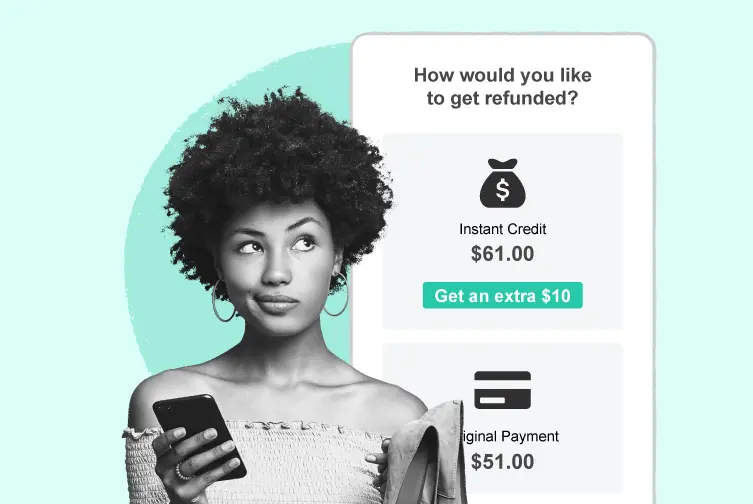

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Easy claims and smart upsells

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Equip your team for precise return checks.

Easy claims and smart upsells

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

Do you ever wonder how successful retailers manage their inventory to maximize sales and minimize costs? The answer lies in their ability to calculate the inventory turnover. By mastering this crucial aspect of retail operations, businesses can optimize their inventory levels, reduce holding costs, and meet customer demand more effectively.

In this comprehensive guide, we will walk you through the process of calculating inventory turnover, explain its importance in retail success, and provide you with actionable strategies to improve your inventory management. So let’s dive in and unlock the secrets to retail success!

Inventory turnover is not just a number; it’s the heartbeat of your retail business. It guides daily inventory management decisions and strategies promoting growth, playing a vital role in retail success. Indeed, calculating inventory turnover helps avoid overstocking and understocking issues.

Gaining insights into your company’s inventory turnover can help you make more informed decisions related to pricing, manufacturing, marketing, and purchasing. Furthermore, optimizing inventory turnover can lead to decreased overhead costs, including storage fees and expedited shipping costs, as well as a competitive edge in the market.

In the retail sector, inventory turnover is a key performance indicator that reflects the efficiency of your inventory management. A high inventory turnover ratio signifies successful business operations with rapid inventory sales. Conversely, a low turnover may point to inefficient inventory management, resulting in increased holding costs and potential cash flow issues.

Calculating inventory turnover ratios helps determine which products to discontinue and the reorder quantity for items with low turnover. Moreover, tracking inventory turnover over time can help you identify seasonal trends or geographical pockets of demand, enabling you to make data-driven decisions that will boost your bottom line.

A high inventory turnover rate is generally considered a positive sign, as it indicates that your inventory is being sold efficiently. However, an excessively high turnover can signify inefficient purchasing and inadequate inventory, leading to stock deficiencies and decreased sales. As such, establishing performance benchmarks and maintaining a balance between supply and demand is crucial for retail success.

The inventory turnover ratio also aids in preventing backorders by ensuring popular items are ordered in advance and in sufficient quantities to satisfy customer needs. By maintaining a balance between supply and demand, retailers can optimize their inventory levels, reduce carrying costs, and maximize sales.

The inventory turnover ratio, a crucial metric, quantifies how often a company’s inventory is replaced relative to its cost of goods sold (COGS) over a designated period. Inventory turnover ratio measures can vary depending on the industry and the type of products being sold. For instance, fast-moving consumer goods should have a higher turnover rate compared to slow-moving consumer goods.

A high inventory turnover ratio is generally indicative of healthy sales and effective inventory management. However, it’s vital to account for unique factors like industry, product types, and market trends that shape the optimal inventory ratio for your business. To achieve a balance between profitability and efficiency, retailers must continuously monitor and adjust their inventory turnover strategies to ensure they align with changing market conditions and customer demands, aiming for a good inventory turnover ratio.

Inventory turn and stock turnover are two terms used to describe the rate at which a company’s inventory is sold and replaced over a specific period. Both terms are essential for understanding the efficiency of your retail operations and making informed decisions regarding purchasing, production, and pricing strategies.

In essence, a higher inventory turnover rate implies that your business is effectively managing its inventory and meeting customer demands.

Strategic inventory management revolves around striking the right balance between profitability and efficiency. This balance is key to retail success as it helps cut costs, boost sales, and improve customer satisfaction.

One way to balance profitability and efficiency is through effective demand forecasting and planning, which assists in investing in the necessary inventory and safety stock to meet customer needs without inadvertently overstocking. Another key aspect is optimizing supply chain management to ensure timely and cost-effective product deliveries. Lastly, implementing pricing and promotion strategies can help drive sales and prevent an accumulation of unsold inventory.

To calculate the inventory turnover ratio, simply use the inventory turnover ratio formula, which involves dividing the cost of goods sold (COGS) by the average inventory value. This simple formula provides valuable insight into the efficiency of your inventory management.

By monitoring and adjusting your inventory turnover ratio as needed, you can optimize your operations, reduce carrying costs, and ultimately boost your bottom line.

Having understood the inventory turnover calculation formula, it’s time to delve into its components – cost of goods sold (COGS) and average inventory value. These two elements play a crucial role in determining your inventory turnover ratio and provide valuable information about the effectiveness of your inventory management practices.

By understanding the components of inventory turnover, you can make informed decisions about how to optimize your inventory.

The cost of goods sold (COGS) encompasses the total cost of inventory sold during a certain period, accounting for the cost of goods purchased, labor costs, and any related production costs.

It’s important to accurately calculate COGS, as it directly impacts the inventory turnover ratio and ultimately the efficiency of your inventory management practices.

The average inventory value is the mean cost of the inventory held by a company over a particular period. To calculate the average inventory value, you need to take the sum of the cost of the inventory at the start and the end of the period and divide it by two. This figure provides a snapshot of your inventory levels and helps you understand the effectiveness of your inventory management practices.

Understanding both COGS and average inventory value enables accurate calculation of your inventory turnover ratio, informing your inventory management strategies accordingly. This, in turn, will help you reduce holding costs, increase sales, and ultimately boost your bottom line.

Let’s illustrate inventory turnover calculation with some practical examples for better understanding. These practical demonstrations will help you see the formula in action and give you a clearer understanding of how to apply it to your own business.

Imagine a company that sold 10,000 units in a year and had an average of 5,000 units on-hand. To calculate inventory turnover, we would divide the number of units sold (10,000) by the average number of units on-hand (5,000), resulting in an inventory turnover of 2.

On average, it takes 264,31 days to sell the stock. This suggests that the stock turnover is slow. By understanding and applying the inventory turnover formula to everyday scenarios like this, businesses can gain valuable insights into their inventory management practices and make data-driven decisions to optimize their operations.

After calculating your inventory turnover ratio, it’s important to analyze and interpret this data to guide your business decisions. A high inventory turnover ratio, for example, indicates that your business is efficiently selling its inventory and operating successfully. On the other hand, a low inventory turnover ratio may suggest inefficiencies in your inventory management practices, leading to increased holding costs and potential cash flow problems.

By regularly monitoring and analyzing your inventory turnover ratios, you can:

Identify areas of improvement

Adjust your inventory management strategies accordingly

Optimize your operations

Reduce carrying costs

Ultimately increase your bottom line.

While analytics data about inventory turnover is clearly very important, tying it in to other key data points about the business is even more important. With WeSupply, you can get the full picture by leveraging comprehensive analytics about logistics, shipments, order data and returns.

Several strategies can be implemented to enhance inventory turnover. These strategies include:

Demand forecasting and planning

Efficient Supply Chain Management: Streamlining Operations. Using post-purchase tools like WeSupply allows for automatic inventory restocking when products are returned, where relevant

Pricing and promotion strategies

Leveraging technology in inventory management

By implementing these strategies, businesses can enhance their inventory management practices, reduce costs, and ultimately boost their profitability.

Let’s examine each of these strategies and their role in improving inventory turnover.

Effective demand forecasting and planning play a key role in optimizing inventory turnover. By accurately predicting customer demand and planning the appropriate amount of inventory to meet this demand, businesses can minimize the risk of overstocking or understocking, which could lead to lost sales or excess inventory costs.

Employing predictive tools and analyzing historical sales data can help businesses make more informed decisions regarding their inventory levels, ultimately improving their inventory turnover.

Another key strategy for improving inventory turnover is streamlining operations through efficient supply chain management. By optimizing their supply chain operations, businesses can:

Ensure timely and cost-effective product deliveries

Reduce the risk of stockouts or overstocking

Better align their inventory levels with customer demand

Minimize the risk of unsold inventory

Maximize sales

Effective supply chain management is crucial for improving inventory turnover and overall business performance.

In addition to optimizing operations, businesses should also focus on building strong relationships with suppliers. This can help secure better pricing, negotiate more favorable terms, and ensure a reliable supply of inventory to meet customer demand.

Balanced inventory turnover can also be achieved through:

Tactical pricing

Promotion strategies

Adjusting prices to meet customer demand

Offering promotional incentives to boost sales

Utilizing data to inform decisions

These strategies can all help improve inventory turnover.

By carefully considering pricing and promotion strategies, businesses can strike the right balance between supply and demand, ultimately enhancing their inventory management and boosting their bottom line.

In the dynamic retail landscape of today, technology utilization is imperative for inventory turnover optimization. Automated inventory management systems and inventory management software can help businesses streamline their operations, reduce costs, and enhance customer satisfaction. By embracing technology, retailers can gain a competitive edge and significantly improve their inventory management practices.

Let’s delve into how technology is transforming inventory management and aiding businesses in enhancing their inventory turnover.

Automated inventory management systems are transforming the way businesses manage their inventory. These systems provide:

Real-time visibility into inventory levels

Automation of processes such as tracking stock levels and reordering products

Production of valuable reports that help businesses make informed decisions.

By implementing automated inventory management systems, retailers can significantly reduce the time and effort required to manage their inventory, ultimately leading to improved inventory turnover and increased profitability.

WeSupply Labs stands out as a transformative technology, assisting merchants in ensuring a seamless post-purchase journey for their online customers. It integrates vital services like self-service order tracking, proactive alerts, and returns management, all aimed at elevating customer contentment and driving sales. Specifically concerning returns, WeSupply simplifies the process by facilitating item restocking upon receipt, streamlining inventory management.

Using cutting-edge tools like WeSupply Labs, businesses can amplify their performance, witnessing consistent growth across all parameters

Returns management made easy for your team

Book a quick call with our experts to see how WeSupply can help you streamline your return management.

As the retail industry continues to evolve, inventory management software is playing an increasingly important role in optimizing inventory turnover. These tools provide businesses with real-time visibility into their inventory levels, analytics capabilities, and data tracking functionalities that help them make more informed decisions regarding their inventory management.

By embracing the latest inventory management software solutions, businesses can streamline their operations, reduce costs, and ultimately boost their bottom line.

Inventory turnover management is a complex undertaking requiring a delicate balance among various factors. To succeed in this endeavor, businesses must be aware of the best practices, considerations, and challenges associated with inventory turnover management.

Utilizing open-to-buy systems, maintaining supply-demand balance, comprehending the average inventory value, and sidestepping common inventory turnover errors can help businesses optimize their inventory management practices for retail success.

Open-to-buy systems are an effective tool for prudent purchasing decisions. These systems provide an estimate of the inventory that must be acquired to meet customer requirements, helping businesses plan their purchases and avoid scenarios of overstocking or understocking.

By incorporating open-to-buy systems into their inventory management processes, businesses can ensure they are purchasing the right amount of inventory at the right time, ultimately improving their inventory turnover.

Maintaining a balance between supply and demand is critical to avoiding the peril of dead stock. Dead stock refers to inventory that is not selling or generating revenue, leading to financial losses, increased storage costs, and reduced cash flow.

By carefully monitoring inventory levels and adjusting purchasing decisions accordingly, businesses can minimize the risk of dead stock and optimize their inventory management practices.

Comparative analysis and seasonal skews can present significant challenges when calculating inventory turnover. These factors can distort the inventory turnover ratio, leading to inaccurate conclusions and potentially detrimental business decisions.

To avoid these pitfalls, businesses should carefully consider the unique factors that influence their inventory turnover ratio and make adjustments as needed to ensure accurate calculations.

Managing inventory for high-cost items requires a delicate balance between supply and demand. These items represent a significant investment for a business, and managing their inventory effectively is essential to optimize this investment and minimize the risk of obsolescence or spoilage.

By employing strategies such as demand forecasting and planning, efficient supply chain management, and pricing and promotion strategies, businesses can find the right equilibrium for their high-cost items and improve their inventory turnover.

Retailers often fall into the traps of over-ordering and data collection errors. Over-ordering can result in an accumulation of excess stock and increased costs, while data collection errors can lead to inaccurate inventory data and difficulty in managing inventory.

By being aware of these common pitfalls and implementing strategies to avoid them, retailers can optimize their inventory management practices and enhance their overall business performance.

Some common inventory turnover mistakes include:

Inaccurate tracking of inventory levels

Inadequate demand forecasting

Inefficient supply chain management

Inadequate pricing and promotion strategies

By being aware of these common mistakes and implementing best practices to avoid them, businesses can improve their inventory management practices and ultimately boost their bottom line.

In conclusion, inventory turnover is a key pillar of retail success. By mastering the art of calculating and understanding inventory turnover, businesses can optimize their inventory management practices, reduce holding costs, and meet customer demand more effectively.

By implementing the following strategies, businesses can enhance their profitability and ensure long-term success

Demand forecasting and planning

Efficient supply chain management

Pricing and promotion strategies

Leveraging technology in inventory management

Utilizing advanced software like WeSupply to enhance the post-purchase journey

In summary, inventory turnover is a key performance indicator that provides invaluable insights into the efficiency of a company’s inventory management practices. By calculating and understanding inventory turnover, businesses can optimize their operations, reduce carrying costs, and maximize sales. Implementing strategies such as demand forecasting and planning, efficient supply chain management, pricing and promotion strategies, and leveraging technology in inventory management can greatly improve inventory turnover and ultimately boost a business’s bottom line.

To calculate inventory turnover, divide the cost of goods sold (COGS) for a given period by the average inventory for that same period. The average inventory is calculated by adding the beginning and end inventories for the period and dividing by two.

This will give you an indication of how many times the inventory has been turned over in a given period.

The formula for calculating inventory is (COGS + ending inventory) – purchases.

This means adding the cost of goods sold (COGS) and the most recent ending inventory and subtracting the money spent on new inventory purchases to calculate beginning inventory.

To calculate inventory turnover in Excel, you can divide sales by inventory or COGS by average inventory. Both methods are simple and effective.

In general, a higher inventory turnover ratio is seen as positive and indicates efficient inventory management and good sales.

This ideal ratio will depend on the specific industry and products being sold.

To improve your inventory turnover, consider demand forecasting and planning, implementing efficient supply chain management, pricing and promotion strategies, and leveraging technology in inventory management.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

What does in transit mean and how long does it take? Read this article to find out & see how to answer your customers’ burning questions.

In this post we’ll explore the RMA meaning, discussing what RMAs are, best practices for managing them effectively and more.

In this blog post, we’ll guide you through the secrets of successful parcel contract negotiation and how to overcome common challenges.

Shipping costs impact your business. Let’s explore how to accurately calculate shipping costs to boost sales and customer satisfaction.

In this guide, we’re going to help you understand how to work out your return rate and how to improve your returns process to increase profits.

In this blog post, we will delve into the various types of shipping exceptions, and how businesses can effectively manage them.

What does in transit mean and how long does it take? Read this article to find out & see how to answer your customers’ burning questions.

How to forecast demand, consumer behavior, and shopping trends? Find out all about it here: from seasonality to supplier lead time, and more!

What are private label products and how you can use them to kickstart your eCommerce business? Read this article to find out!