Safety stock calculator excel [Download Free Template]

Discover how safety stock can transform your retail business and prepare you for the future of customer-centric inventory management.

Shipping, Tracking & Notifications

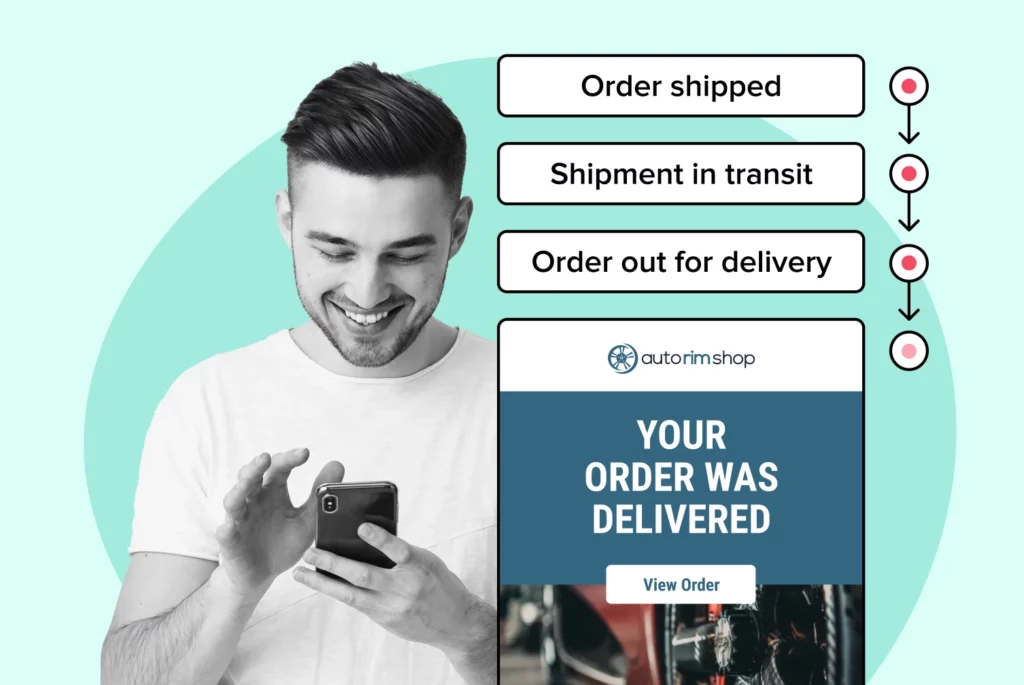

Boost customer experience and reduce support tickets

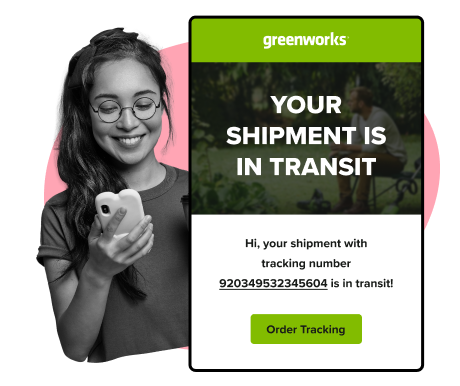

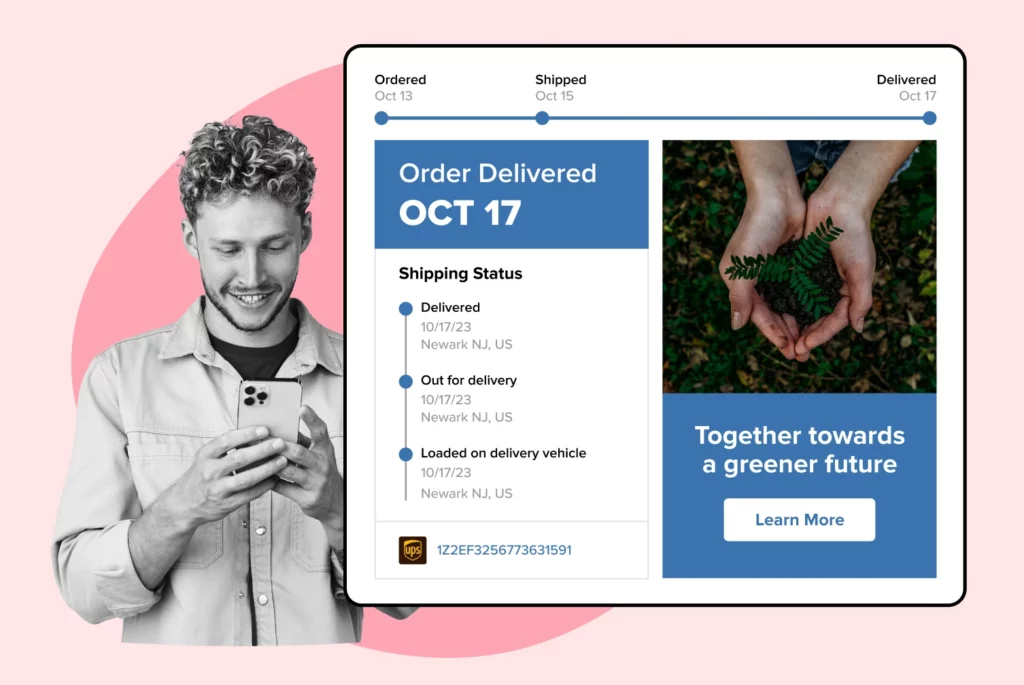

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

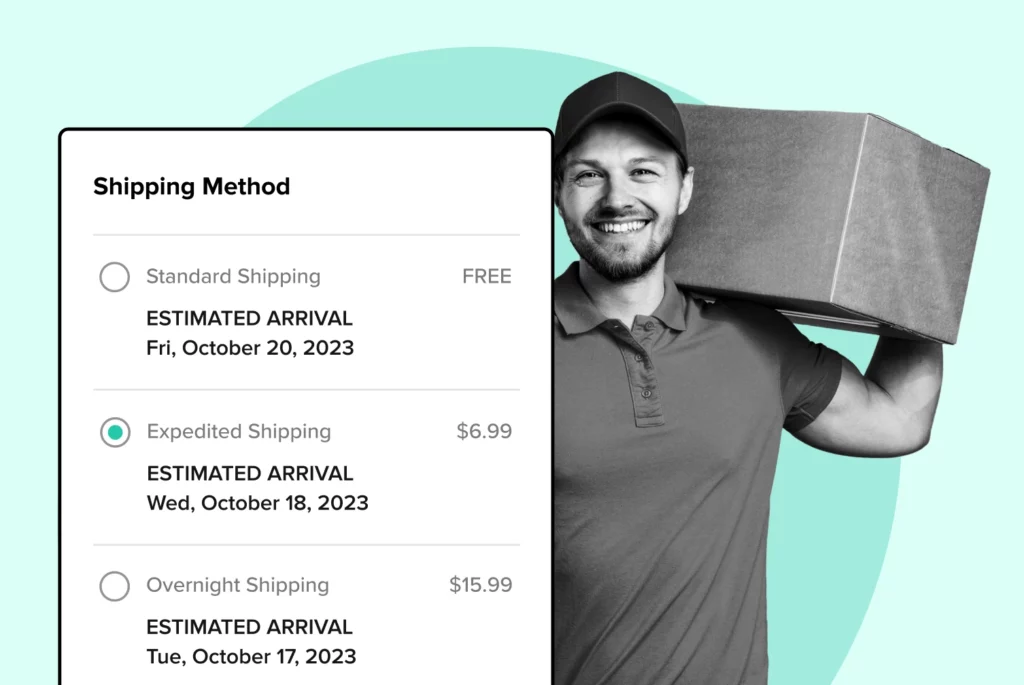

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Easy claims and smart upsells

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Equip your team for precise return checks.

Easy claims and smart upsells

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

In the fast-paced world of logistics, businesses are always seeking ways to streamline operations and reduce costs. Enter cross-docking, a strategy that revolutionizes supply chain management by directly transferring goods from inbound to outbound transport, eliminating storage and operational costs. In this comprehensive guide, we’ll delve into the concept of cross-docking and explore its history, benefits, challenges, and best practices, so you can decide if it’s the right solution for your business.

Cross-docking is a logistics strategy that streamlines supply chain management and reduces costs.

It has been shaped by the U.S trucking industry and modern technology, providing businesses with various benefits such as faster delivery times, improved efficiency, customer satisfaction & increased profitability.

To remain competitive in today’s market, businesses must stay informed of its evolution & leverage its advantages while utilizing automation & real time tracking for optimal operations.

Integrating WeSupply’s optimized post-purchase platform enhances eCommerce processes by strategically utilizing its advanced features in Order Tracking, Shipping Notifications, and Returns & Exchanges, thereby elevating both inbound and outbound logistics to significantly improve the customer experience.

Cross-docking is a logistics strategy that streamlines supply chain management by transferring goods directly from inbound to outbound transport at a distribution docking terminal, utilizing an efficient cross-docking system. This strategy minimizes the need for storage space, reduces inventory handling costs, increases efficiency, and speeds up shipments. Businesses across various industries are adopting cross-docking to optimize their operations and achieve these benefits at cross-docking facilities.

Cross-docking plays a crucial role in modern supply chains by offering a just-in-time fulfillment technique. It involves labeling products at the inbound docking terminal and transferring them directly to the outbound dock of a fulfillment warehouse, thereby minimizing inventory handling. This versatile shipping method reduces the need for distributors, cuts costs, and significantly shortens order fulfillment times. By centralizing product handling and adapting to the unique requirements of different industries, cross-docking has the potential to revolutionize supply chain operations.

Cross-docking has a rich history, dating back to its inception in the US trucking industry in the 1930s. Over the years, it has evolved into a widely adopted logistics practice, thanks in part to the influence of modern logistics technology.

We will traverse through the origins of cross-docking, its evolution over time, and the influential role of the U.S. trucking industry in shaping its processes in the subsequent sections.

Cross-docking originated in the U.S. trucking industry in the 1930s, with companies seeking to enhance the efficiency of their supply chain management systems, expedite the delivery of goods to consumers, and reduce the cost of carrying inventory. Over the years, cross-docking has expanded its reach, with the implementation and improvement of cross-docking processes in the United States during the 1950s.

The growth of cross-docking is attributed to its cost-saving and expedited delivery capabilities. As technology advanced, businesses were able to more effectively track and manage goods during the cross-docking process, leading to further refinement and adoption of this logistics practice across various industries.

The U.S. trucking industry played a pivotal role in the development and adoption of cross-docking processes. By implementing cross-docking, the industry was able to reduce labor costs, optimize inventory management, and facilitate faster shipments.

Despite the potential challenges and complexities associated with cross-docking, such as supply chain vulnerabilities and handling intricacies, the trucking industry’s pioneering efforts laid the groundwork for the widespread adoption of cross-docking in various sectors.

One of the primary benefits of cross-docking is the significant reduction in storage needs and costs. Traditional warehousing involves storing products for extended periods, which incurs substantial expenses for space and maintenance. Cross-docking eliminates the need for long-term storage by ensuring goods are quickly transferred from inbound to outbound transportation. This efficiency not only reduces storage costs but also frees up valuable warehouse space for other purposes.

Inventory handling is a major cost factor in traditional supply chains. With cross-docking, the number of touchpoints for each product is minimized. Products are not stored for long durations and are moved directly from the supplier to the customer or retailer. This streamlined process reduces labor costs associated with loading, unloading, and re-packing goods multiple times, leading to significant savings.

Cross-docking enhances supply chain efficiency by streamlining operations and reducing the time products spend in transit. By bypassing traditional warehousing steps, goods move faster through the supply chain, leading to quicker order fulfillment and delivery. This increased speed is particularly beneficial for time-sensitive products and industries that require rapid transportation.

In today’s competitive market, customer satisfaction is paramount. Cross-docking contributes to improved customer satisfaction by ensuring faster deliveries. When products reach customers quickly and reliably, it enhances their shopping experience and builds trust in the brand. Faster deliveries also allow businesses to respond more effectively to market demands and seasonal fluctuations.

Perishable goods such as food and pharmaceuticals require swift transportation to maintain their quality and safety. Cross-docking is particularly advantageous for these products as it reduces the time they spend in transit. By moving perishable goods directly from the supplier to the customer, cross-docking helps maintain product freshness and minimizes the risk of spoilage.

The entire logistics chain, from warehouse operations to the hands of the customer, experiences a transformative boost with the integration of post-purchase software like WeSupply. Central to this enhancement is the system’s adeptness at Order Tracking and Proactive Shipping Notifications. By offering real-time, pinpoint tracking details, WeSupply removes the opacity that often surrounds the transit phase of the order journey, providing both businesses and customers with unparalleled visibility. This transparency fortifies customer trust, as they are no longer in the dark about their order’s status or unexpected delays.

Moreover, proactive shipping notifications ensure customers are instantly informed about their shipment’s progress, reinforcing their sense of engagement and connection with the brand. This consistent communication significantly reduces customer anxiety, potentially cutting down customer service costs related to tracking inquiries, and sets the stage for a more reliable and satisfying customer experience. Through these advanced functionalities, WeSupply elevates the conventional logistics process into a customer-centric journey that drives loyalty and repeat business.

Cross-docking can be categorized into continuous, consolidation, de-consolidation, pre-distribution, and post-distribution types, each with its unique advantages and applications.

We will examine the diverse types of cross-docking and their respective pros and cons in the upcoming sections, offering a holistic understanding of the distinct strategies available to businesses.

Continuous cross-docking involves a constant flow of goods, minimizing storage time and maximizing efficiency. This type of cross-docking ensures that products are transferred directly from inbound to outbound shipments, reducing the need for storage space and leading to faster delivery times and cost savings. Continuous cross-docking is particularly beneficial for industries requiring rapid transportation of goods between locations.

Keeping customers updated with accurate delivery estimates significantly enhances their satisfaction levels. With tools like WeSupply, businesses can prominently showcase Estimated Delivery Dates for every shipping option, right from the product page to the checkout. Moreover, by using WeSupply’s post-purchase notification system, customers are continuously informed about each step of their order’s journey, thereby minimizing uncertainties and boosting their overall shopping experience.

Eliminate shipping anxiety

Book a quick call with our experts to see how WeSupply can help you set the appropriate expectations from the start and boost your conversion along the way.

Consolidation cross-docking combines multiple shipments into a single shipment to lower transportation costs, while de-consolidation cross-docking divides large loads into smaller ones for expedited delivery to customers. Both methods offer different advantages depending on shipment size and destination.

For example, consolidation can result in cost savings for shipping, while de-consolidation may lead to reduced handling and transportation costs.

Pre-distribution cross-docking involves consolidating goods from suppliers into a single shipment before sending them out to customers, while post-distribution cross-docking breaks down goods from suppliers into smaller shipments before sending them out to customers. Both methods focus on optimizing supply chain operations, but each offers distinct advantages depending on the specific needs of the business.

Pre-distribution cross-docking reduces the amount of time inventory spends in the warehouse, which can be particularly beneficial for businesses requiring rapid transportation of goods between locations. On the other hand, post-distribution cross-docking allows distributors and retailers to make informed decisions regarding the delivery of inventory to the most appropriate location, taking into account inventory forecasting figures and current inventory levels. This strategic approach to shipping can result in significant cost savings and improved customer satisfaction.

Cross-docking extends a plethora of benefits such as accelerated shipments, cost savings, and consolidated product handling. We will further explore the advantages of cross-docking, the potential challenges and intricacies, and the best practices for successful implementation in the subsequent sections.

Cross-docking provides a range of benefits, such as accelerated shipping times, reduced costs, and streamlined supply chain management. By minimizing storage duration and optimizing efficiency, businesses can expedite delivery times and reduce costs, ultimately leading to improved customer satisfaction and increased profitability.

In addition to these advantages, cross-docking can also lead to better inventory management and enhanced customer service. By centralizing product handling and eliminating the need for storage, businesses can more effectively manage their inventory levels and respond to customer demands in a timely manner.

Centralizing product handling through cross-docking can lead to strategic advantages and improved efficiency. Some benefits of cross-docking include:

Consolidating goods from multiple suppliers at a single location

Streamlining operations and reducing handling time

Saving on shipping and storage costs

This central location approach to product handling makes cross-docking an invaluable logistics strategy for businesses looking to optimize their supply chain operations at a distribution center.

While cross-docking offers numerous benefits, it can also present challenges, such as supply chain vulnerabilities, reduced supplier options, and handling complexities.

In the following sections, we’ll examine the potential drawbacks of cross-docking and discuss how businesses can overcome these challenges to reap the full benefits of this logistics strategy.

Cross-docking can pose potential challenges, including supply chain disruptions, limited supplier choices, and increased handling complexities. Supply chain vulnerabilities may arise due to the limited number of suppliers and the necessity for accurate timing of deliveries. Handling complexities can also be a challenge, as cross-docking requires thorough planning and coordination to guarantee deliveries are prompt and in the appropriate order.

Reducing the number of suppliers through cross-docking can have both positive and negative implications for businesses. On one hand, it may result in cost reductions, increased efficiency, and expedited delivery times. On the other hand, a decrease in suppliers can lead to an increased risk of supply chain disruption, complexity, and costs.

Businesses must carefully weigh the pros and cons of reducing suppliers when implementing cross-docking strategies.

Effective implementation of cross-docking necessitates compliance with best practices, optimal warehouse design, and efficient scheduling. We will discuss the norms for successful cross-docking execution and delve into the various supportive technologies and software in the ensuing sections.

Following best practices for cross-docking implementation can ensure success and maximize benefits. These practices include optimizing warehouse design and layout, ensuring efficient scheduling, and managing dock doors effectively. By adhering to these guidelines, businesses can optimize their cross-docking operations and reap the full benefits of this logistics strategy.

Proper warehouse design and layout are crucial for successful cross-docking operations. By maximizing space utilization and minimizing travel distance, businesses can ensure that their cross-docking processes run smoothly and efficiently.

Additionally, optimizing warehouse design can help achieve minimal storage space, reduce warehouse storage costs, and enhance overall supply chain efficiency.

Effective scheduling and dock door management are essential for optimizing cross-docking processes. Businesses must create detailed schedules, monitor shipments, and utilize technology to automate processes in order to guarantee timely and efficient deliveries.

Furthermore, proper dock door maintenance and employee training are crucial to maximizing productivity and ensuring the success of cross-docking operations.

Several industries, such as automotive, food and beverage, and ecommerce, can leverage cross-docking strategies customized to their specific needs. We will investigate the different industries that gain from cross-docking and discuss how these strategies can be adapted to meet the distinctive requirements of each sector in the upcoming sections.

Cross-docking is a valuable logistics strategy for industries with time-sensitive products or those that rely on multiple suppliers. Industries such as automotive, food and beverage, consumer goods, chemicals, and retail have found cross-docking to be particularly advantageous, as it enables them to reduce inventory costs, expedite product delivery, and improve customer satisfaction.

Industries utilizing cross-docking can significantly benefit from an enhanced post-purchase journey, from order placement to product reception, with WeSupply. This platform, vital for ensuring streamlined operations, features exact Estimated Delivery Dates, steadfast Order Tracking, swift Shipping Notifications, and a self-service Returns Center. WeSupply not only transforms eCommerce challenges into advantages but also fortifies customer satisfaction in industries where timely delivery is paramount.

Fully customizable Branded Tracking page and Email Notifications

Book a quick call with our experts to see how WeSupply can help you tell your brand story, promote new categories or showcase your latest sale.

Adapting cross-docking strategies to suit the unique requirements of different industries can lead to significant benefits and efficiencies. For example, businesses dealing with perishable goods or cold food chain products can leverage cross-docking to ensure their products reach customers as quickly as possible, minimizing waste and maximizing freshness.

By tailoring cross-docking strategies to the specific needs of each industry, businesses can optimize their supply chain operations and reap the full benefits of this logistics approach.

Cross-docking operations can be ameliorated using cutting-edge technologies and software like automation and real-time tracking. We will probe into how the integration of contemporary technology can augment the efficiency of cross-docking processes and provide businesses with a competitive advantage in the subsequent sections.

Utilizing modern technologies and software can help businesses optimize their cross-docking operations and achieve better results. Solutions such as warehouse management systems, automated sorting systems, and transportation management systems can streamline processes, cut costs, and enhance efficiency. By leveraging these advanced technologies, businesses can stay ahead of the competition and maximize the benefits of cross-docking.

Embracing automation and real-time tracking can lead to improved efficiency and accuracy in cross-docking processes. Some benefits of incorporating these advanced technologies into cross-docking operations include:

Eliminating human errors and reducing manual data entry through automation

Enhancing visibility and facilitating prompt decision-making with real-time tracking

Optimizing supply chain management

Achieving greater success in cross-docking operations

For example, WeSupply’s Branded Tracking Page functionality not only allows your users to follow their package every step of the way, it also allows for consolidation of loyalty to your brand, giving you ample opportunities to showcase your company, as well as upsell products and build trust.

WeSupply, an innovative post-purchase software, adeptly intertwines technology and customer experience to optimize e-commerce logistics. It effortlessly integrates with numerous third-party applications and global shipping couriers, ensuring smooth inventory management and delivering precise, timely order updates to customers, thereby mitigating shipping anxieties.

Simultaneously, it transforms post-purchase interactions by providing accurate delivery forecasts and personalized product suggestions, embodying a holistic approach that blends operational efficiency with enriched customer engagement, solidifying brand loyalty and amplifying overall satisfaction in the digital shopping landscape.

With the ongoing evolution of cross-docking, it is vital for businesses to stay updated and ready to modify their strategies to stay competitive in the dynamic logistics landscape. By comprehending the benefits, challenges, and best practices linked with cross-docking, businesses can make informed decisions and optimize their supply chain operations for peak efficiency and profitability.

The future of cross-docking will likely see further advancements and innovations, driven by the continued growth of ecommerce and the increasing demand for efficient supply chain solutions. As technology continues to advance, businesses must stay informed and prepared for what’s to come in order to remain competitive in this ever-evolving landscape.

By leveraging the benefits of cross-docking and embracing modern technology, businesses can optimize their logistics operations and achieve long-term success.

In conclusion, cross-docking is a powerful logistics strategy that offers numerous benefits, such as faster shipments, cost savings, and centralized product handling. By understanding the history, types, and best practices of cross-docking, businesses can optimize their supply chain operations and stay competitive in the ever-changing logistics landscape. As cross-docking continues to evolve, it’s essential for businesses to stay informed and prepared for what’s next in this dynamic field.

In the multifaceted arena of supply chain operations, especially where cross-docking plays a crucial role in expediting product movement from suppliers to consumers, WeSupply proves invaluable for e-commerce businesses. It meticulously elevates the post-purchase journey, assuring an enriched, seamless experience even after a transaction. WeSupply’s nuanced features, which cohesively streamline interactions between various logistical stages, validate its allegiance to quality and persistent reliability during the post-purchase interval, ensuring efficient and transparent product transitions in cross-docking scenarios.

Cross-docking is a supply chain process where goods are unloaded from incoming transport, sorted and immediately loaded onto outbound vehicles with minimal storage space in between. This process reduces storage costs and inventory levels while being used in various industries such as retail, manufacturing, logistics and the LTL trucking industry.

An example of cross-docking is Wal-Mart’s use of their distribution centers to receive goods from suppliers, process them and send them to stores within 130 miles of the center. Additionally, goods may be moved from a train car to a truck or cargo containers from a ship to a truck with little to no handling or storage. Moreover, retail giants like Wal-Mart sort items for delivery to specific store locations, making use of a hub-and-spoke system similar to airports.

Cross-docking is a trucking process that involves unloading inbound freight from one truck, holding it for a very brief period and then loading it onto another truck for outbound shipping. It removes the “storage” link of the supply chain, allowing products to continue their journey without delay.

Cross-docking is a useful supply chain tool, with five distinct types: Distributor Cross-Docking, Manufacturer Cross-Docking, Retail Cross-Docking, Transportation Cross-Docking and Opportunistic Cross-Docking. Each type has its own unique purpose.

Cross-docking has proven advantageous for automotive, food and beverage, consumer goods, chemicals, and retail industries, reducing inventory costs, expediting product delivery, and improving customer satisfaction.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

Discover how safety stock can transform your retail business and prepare you for the future of customer-centric inventory management.

Join us as we explore the what, why, and how of the shift towards carbon neutral shipping in the world of logistics.

In this post, we’ll dive into the world of 4PL logistics, its benefits, challenges, and how it compares to more traditional logistics models.

This article offers a detailed comparison of standard and expedited shipping in e-commerce, helping you make informed logistics choices.

As we dive into the intricacies of inbound logistics, we will explore its challenges, as well as best practices for optimizing its processes.

In this blog post, we’ll explore the ins and outs of SFP, including eligibility requirements, advantages, and strategies for success.

Read on to discover the world of pick lists, their components, and how they contribute to the smooth operation of warehouses.

This blog post explores outbound logistics in e-commerce, its challenges, and optimization best practices.

In this blog post, we will explore the importance of dunnage across various industries, its many forms, and the benefits it offers.