The Link Between Shipping and Return Rates: A Hidden Connection

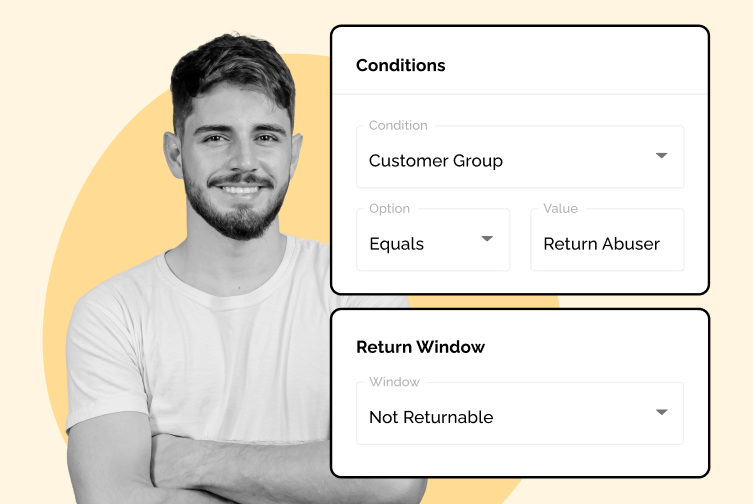

Discover effective strategies to prevent return promo abuse with smart logic. Enhance your business’s integrity!

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

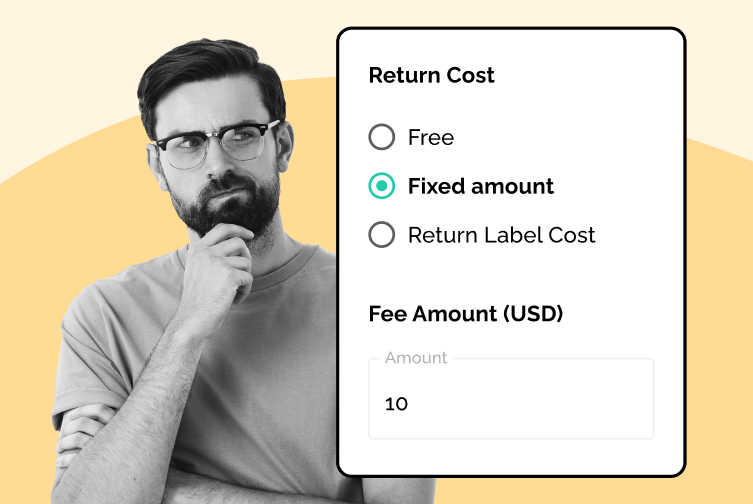

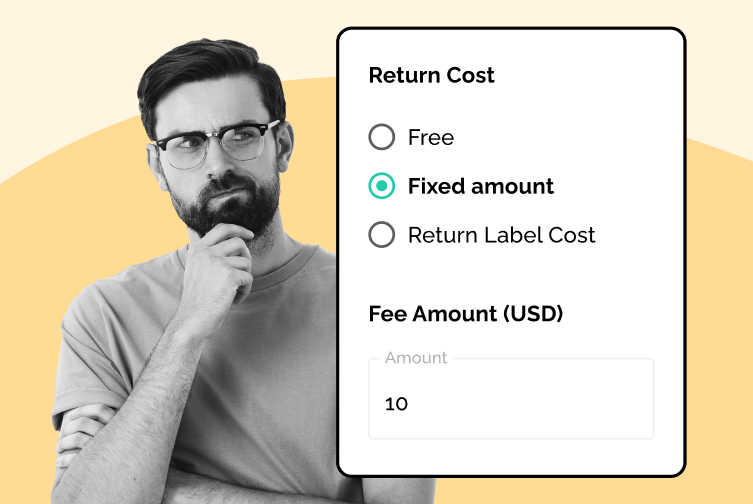

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

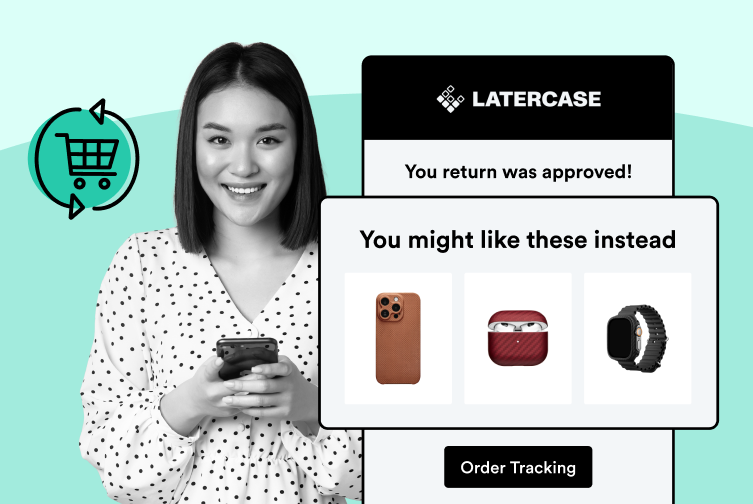

Easy claims and smart upsells

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

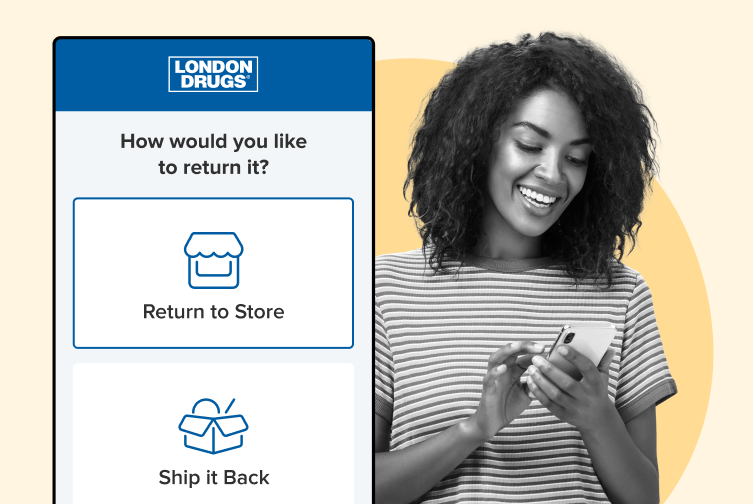

Hassle-free pickup experience for customers

In-Store dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

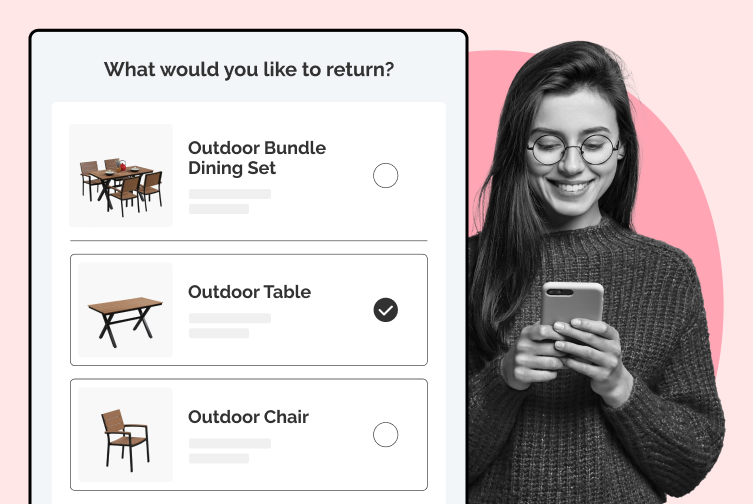

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Equip your team for precise return checks.

Easy claims and smart upsells

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

In the fast-paced world of ecommerce, few challenges can test a brand’s reputation and operational strength like backorders and shipping delays during peak seasons. Whether it’s Black Friday, Cyber Monday, or a holiday rush, customers are placing high-value orders with high expectations—and any misstep in fulfillment can result in lost sales, damaged trust, and costly support tickets.

The backorder process and fulfillment process are critical to managing customer expectations and maintaining operational efficiency during peak seasons, as they ensure accurate inventory tracking, transparent communication, and timely delivery.

But here’s the good news: with the right strategy, backorder management and stock delay communication can become powerful tools for retaining customer loyalty and even boosting revenue. Effective backorder management also supports cash flow by ensuring ongoing sales and timely inventory replenishment. This article walks you through everything you need to know to effectively manage backorders and communicate delays with empathy and efficiency—especially during peak shopping seasons.

Backorder management is a vital component of effective inventory management, especially for businesses aiming to maintain customer satisfaction and keep sales flowing during periods of high demand. When products are temporarily unavailable, how you handle those orders can significantly impact customer loyalty and your bottom line. Without a solid backorder management process, stock shortages can quickly lead to lost sales, frustrated customers, and operational inefficiencies.

Implementing best practices in backorder management helps businesses minimize the negative effects of out of stock situations. By proactively managing backordered items, you can keep customers informed, reduce the risk of losing sales, and ensure that your fulfillment processes remain as efficient as possible. Ultimately, effective backorder management is about balancing inventory levels with customer expectations, so you can deliver exceptional customer experiences—even when inventory challenges arise.

A backorder occurs when a customer places an order for a product that is currently out of stock, but the business expects to restock and fulfill the order in the near future. This is different from a standard out of stock situation, where the item is simply unavailable for purchase until inventory is replenished. Backorders often arise when demand exceeds supply, manufacturing delays disrupt production schedules, or supply chain disruptions impact inventory replenishment.

Understanding why backorders occur is essential for developing strategies that minimize customer dissatisfaction and lost sales. Common causes include sudden spikes in customer demand, unexpected supply chain challenges, and delays from suppliers or manufacturers. By analyzing historical sales data and monitoring demand patterns, businesses can better anticipate when backorders are likely to happen and plan accordingly.

To manage backorders effectively, companies need robust inventory management systems that provide real-time visibility into stock levels and order status. Accurate demand forecasting and transparent communication with customers are also key to maintaining trust and managing expectations during backorder periods. By addressing the root causes and keeping customers informed, businesses can turn backorder challenges into opportunities for building stronger customer relationships.

Backorders occur when customer demand exceeds available inventory. While they can be a sign of popularity or viral success, they often come with risks: unsatisfied shoppers, canceled orders, and operational bottlenecks. During peak seasons, these risks are amplified. Supply chains stretch thin, carriers become overloaded, and any weak link in the fulfillment chain becomes glaringly obvious. Clear communication during backorder situations manages customer expectations and preserves trust, helping to maintain customer loyalty even in challenging times.

However, businesses that treat backorder management as a strategic priority rather than a reactive problem can turn stockouts into opportunities. Proper planning and clear communication allow brands to stay in control, protect their reputation, and even build deeper relationships with customers by showing transparency and reliability when it matters most. Effective backorder management also helps in maintaining sales momentum during inventory shortages, ensuring ongoing sales and sustained customer interest despite stock limitations.

The first step in reducing backorders is to prevent them—and that starts with accurate demand forecasting. Look at your historical sales data, especially from previous peak seasons. What products flew off the shelves last year? Were there specific categories that sold out faster than expected? These insights provide a valuable foundation.

Next, consider the current market climate. Are competitors launching aggressive promotions? Are certain trends taking off on social media? Factor in external elements like inflation, buying power, and even cultural shifts that might influence buying behavior.

This is where AI and predictive analytics come into play. Modern forecasting tools can detect patterns that aren’t immediately obvious—such as the correlation between certain product combinations, regional demand spikes, or promotional timing—and turn that into actionable inventory recommendations. Integrating real time inventory management and inventory tracking tools ensures you have up-to-date data, which leads to more accurate demand forecasting and helps prevent overselling or stockouts. Even a simple pre-order campaign can serve as a demand barometer, helping you gauge interest and adjust your inventory orders before the rush begins.

Don’t wait until the next peak season to evaluate how you performed during the last one. Analyzing your backorder data—what items were frequently out of stock, how long it took to fulfill them, and how customers responded—can reveal valuable trends. This analysis helps identify patterns in inventory shortages and potential customer dissatisfaction, allowing you to address these issues before they impact your business. Maybe one supplier was consistently late, or maybe your fulfillment lagged for one particular region.

Tracking backorder rates alongside customer feedback and fulfillment times helps you determine where improvements are most needed. Are you stocking enough of your A-level SKUs? Are your systems flagging low inventory fast enough? With regular data analysis, you can make informed decisions that improve forecasting and fulfillment ahead of the next high-demand period.

While it’s important not to overstock and tie up cash in excess inventory, understocking comes with its own risks. That’s why safety stock is essential—particularly for bestsellers and high-margin products.

Establish reorder points that trigger automated replenishment when inventory hits a certain threshold. When a reorder point is reached, it can automatically generate a purchase order to suppliers, ensuring timely restocking and minimizing the risk of stockouts. Tools that support ABC classification can help you prioritize items based on their impact on your bottom line. A-items (high value and high velocity) should always have priority, while B- and C-items can be managed with more flexibility.

Don’t forget to run inventory audits before each major sales event. These audits help confirm what’s physically available, clear out slow-moving stock, and make room for high-demand products. Automating purchase orders streamlines inventory replenishment and reduces the risk of backorders.

Suppliers are more than just vendors—they’re partners in your customer experience. Share your demand forecasts early, especially if you’re expecting surges in volume. When suppliers know what’s coming, they’re better equipped to prepare and prioritize your orders. Understanding backorder vs out-of-stock scenarios is crucial when negotiating with suppliers, as it helps set clear expectations for fulfillment and delivery timelines.

When comparing backorders vs out-of-stock situations, backorders allow you to continue taking orders and maintain sales momentum, while out-of-stock items halt sales entirely. Communicating these differences to your suppliers helps them plan production and inventory more effectively.

Diversifying your supplier base is another smart strategy. Relying too heavily on a single source can be risky if they experience delays, shortages, or disruptions. Having backup suppliers in place ensures you have flexibility when things don’t go as planned.

Track supplier performance using key metrics such as on-time delivery rates, order accuracy, and responsiveness. Building strong relationships means you’ll be in a better position to negotiate timelines or minimums when the pressure is on.

Your warehouse needs to function like a well-oiled machine during peak season. That means optimizing the layout to minimize pick-and-pack times, placing top-selling products near packing stations, and reducing unnecessary movement across the facility. Improving operational efficiency in the warehouse helps reduce backorder-related delays, ensuring smoother fulfillment and higher customer satisfaction.

If you handle large order volumes, consider using cross-docking—a fulfillment method that moves incoming goods directly to outbound shipping, skipping storage entirely. This speeds up delivery and reduces overhead.

Warehouse Management Systems (WMS) can automate everything from inventory updates to order prioritization, ensuring your team can process orders faster and more accurately. Coupled with flexible staffing, such as hiring seasonal workers or cross-training your existing team, you’ll be better equipped to handle surges without sacrificing quality.

To truly optimize your fulfillment during backorder situations, you need complete visibility. An inventory management system provides real-time visibility into product availability, supporting proactive backorder management and ensuring customers are informed about stock statuses. Inventory Management Systems (IMS) offer real-time updates on stock levels across your entire operation, allowing you to react quickly to shortages or surpluses.

When connected with your CRM, order management tools, and shipping carriers, these systems enable seamless workflows. For example, if a customer places an order for a backordered item, the system can automatically trigger a notification, prioritize restocking, and track fulfillment—all while keeping the customer in the loop.

Predictive logistics capabilities go a step further by forecasting potential fulfillment delays before they occur. This allows your team to course-correct quickly and avoid larger disruptions.

One of the biggest mistakes ecommerce businesses make is staying silent about potential delays. Customers value honesty—and they’re more forgiving when they know what to expect.

Start by adding banners or pop-ups across your website to highlight any known shipping or inventory delays. Use labels like “Ships in 2 weeks” or “Available on Backorder” on product pages to prevent unpleasant surprises. Clearly indicating out of stock items helps manage customer expectations and allows shoppers to make informed decisions, especially when backordering is available. Updating your shipping policy with peak season timelines can further manage expectations.

It’s also smart to address potential delays in your promotional emails or newsletters. Customers browsing your site because of a flash sale or holiday deal will appreciate the heads-up if certain items might not arrive before their desired date.

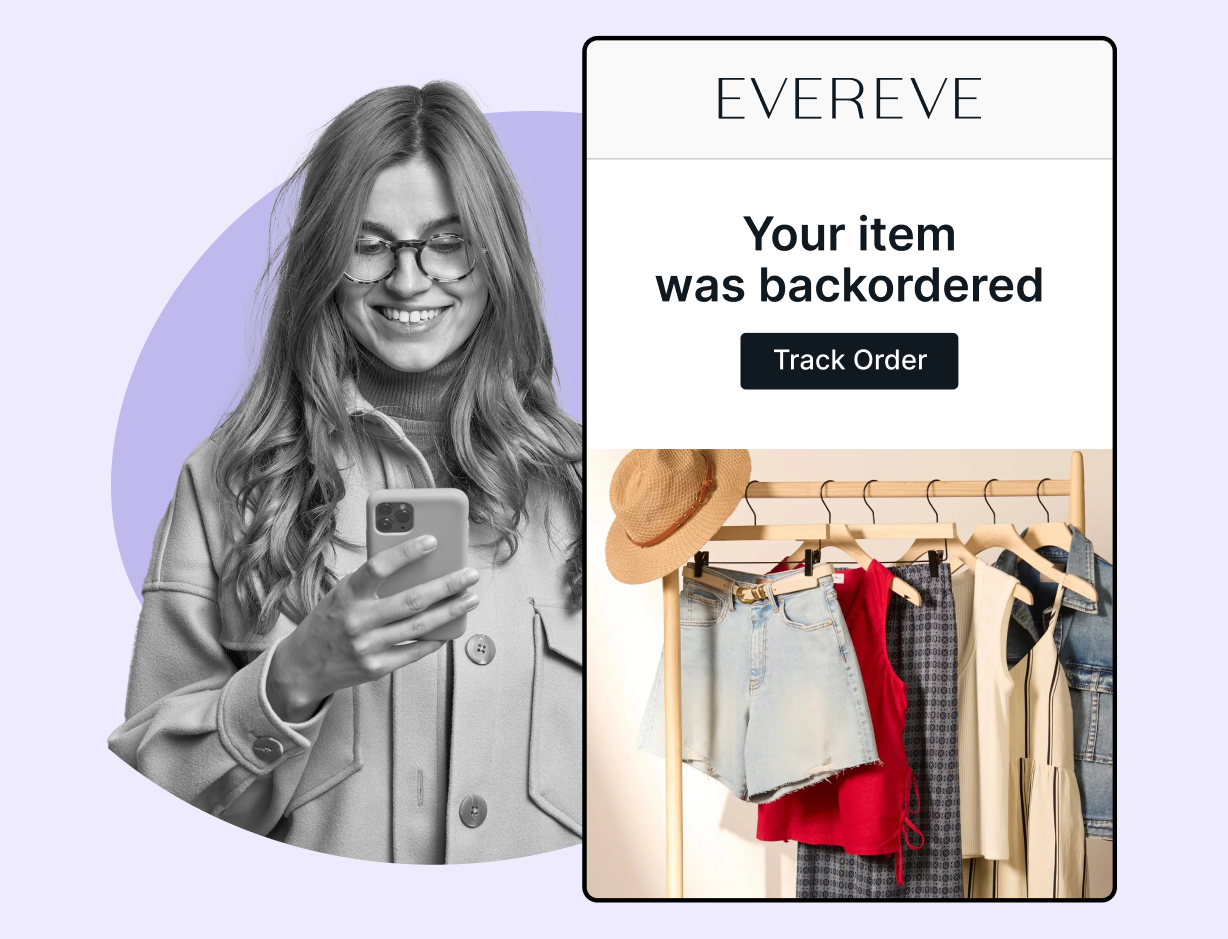

Once the order is placed, communication becomes even more important. Immediately send an order confirmation that includes estimated shipping and delivery timelines—especially for backordered products.

If nothing changes, still send updates. Silence can make customers anxious or irritated. Even a simple “We’re still on track for delivery by [date]” email builds trust and keeps them engaged. Proactive communication like this helps keep customers happy, even when there are backorder delays.

If a delay occurs, don’t sugarcoat it. Be transparent. Your message should include:

A sincere apology

A brief, honest reason for the delay (e.g., supplier issue, shipping carrier backlog)

A new estimated delivery date

A note about what you’re doing to fix the issue

Options: Can they switch to another item? Would they prefer a refund or store credit?

Clear contact information for customer support

This kind of transparency humanizes your brand and shows customers you care.

Relying on just one communication method isn’t enough. Combine several channels to make sure your message gets through:

Email: Great for detailed order updates and delay notifications

SMS: Perfect for quick alerts about changes or delivery confirmations

Website: Add banners or a dedicated FAQ section addressing peak season shipping timelines

Social Media: Notify customers of broader shipping delays and respond to comments or DMs promptly

Customer Support: Train your agents to handle backorder-related inquiries with empathy and accuracy

Integrating customer relationship management tools with these communication channels can further enhance customer satisfaction and loyalty during backorder periods by ensuring personalized and consistent updates.

Together, these channels create a seamless experience that builds trust even in moments of friction.

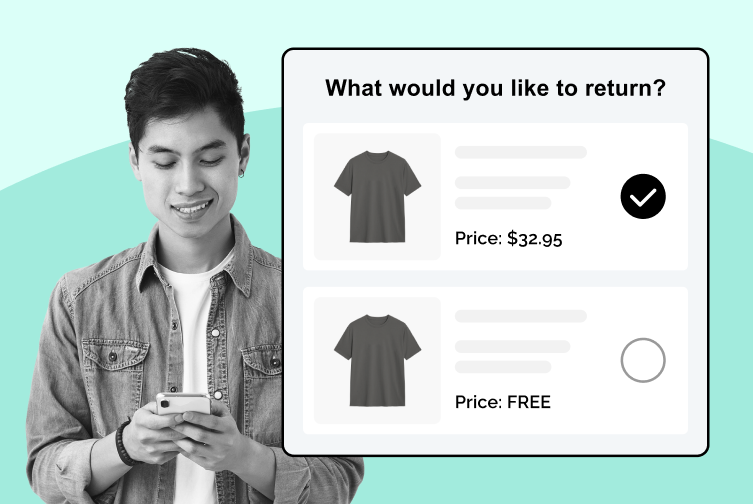

Giving customers choices during backorder situations helps reduce disappointment. Suggest similar products that are in stock, offer free upgrades, or allow them to customize their order to match what’s currently available. It’s important to explain the difference between backordered items vs out of stock items—backordered products can still be purchased with the promise of future delivery, while out of stock items are unavailable for purchase, limiting the options you can offer customers.

Customers appreciate flexibility, especially when it’s framed as a benefit rather than an inconvenience. For example: “We’re experiencing a delay, but we can offer you this similar item with free expedited shipping.”

In cases of significant delays, consider small perks to acknowledge the customer’s patience. A discount code for a future purchase, a partial refund, or free shipping can go a long way toward retaining goodwill. Offering discounts on future purchases is especially effective, as it not only compensates for the inconvenience but also encourages customers to return despite the backorder delay.

Think of these as loyalty investments. The cost of a small gesture is far less than the cost of losing a repeat customer or receiving negative reviews.

Once the item arrives, don’t let the relationship end there. Send a thank-you message that acknowledges the delay and appreciates their patience. Invite them to share feedback on the experience, and consider offering a loyalty incentive for their next order.

This follow-up not only boosts customer retention but also turns a backorder challenge into a trust-building opportunity.

Track your backorder rates, average lead times, and customer sentiment to identify bottlenecks. These metrics help pinpoint which products, processes, or vendors are causing delays.

Analyzing support tickets related to delays or shipping issues can also help you surface recurring problems and improve communication templates or workflows.

The insights you gather during one peak season should inform your strategy for the next. Adjust your forecasting models, tweak supplier contracts, and rework your inventory plans to match evolving patterns.

Use heat maps, sales trends, and customer satisfaction scores to make targeted improvements across your supply chain and communication strategies.

A truly effective backorder strategy depends on integrated systems. Integrated systems are essential for managing backorders efficiently, as they enable seamless coordination between inventory, order management, CRM, and shipping platforms to create a unified, real-time view of every order—especially those on hold.

By automating routine tasks (like customer updates or restock notifications), your team can focus on high-impact improvements. Better still, integration with your suppliers and logistics providers allows for end-to-end visibility and fewer surprises. Leveraging technology in this way helps businesses navigate backorders effectively, particularly during peak shopping seasons when demand and inventory challenges are at their highest.

Backorders and stock delays don’t have to derail your peak season success—especially when you have the right technology on your side. WeSupply helps ecommerce brands transform backorder chaos into confident customer experiences through automation, real-time visibility, and proactive communication.

Whether you’re prepping for Black Friday, Cyber Monday, or the holiday rush, WeSupply gives you the tools to stay one step ahead, keep customers in the loop, and maintain sales momentum even when inventory runs low.

Here’s how WeSupply supports smarter backorder management during peak season:

Self-Service Order Lookup & Tracking

Empowers customers to check the status of their orders, reducing WISMO (“Where is my order?”) tickets and improving satisfaction.

Smart Return & Exchange Options

Offers flexible solutions for customers waiting on delayed items, including exchanges, partial refunds, or choosing a similar in-stock product.

Customizable Backorder Messaging

Display backorder info directly on product pages, emails, or tracking portals—so there are no surprises at checkout or post-purchase.

Analytics for Continuous Improvement

Tracks backorder trends, customer sentiment, and delivery performance so you can optimize inventory planning and communications over time.

With WeSupply, backorder management becomes less of a scramble and more of a strategy. By integrating seamlessly with your existing systems and providing full transparency to your customers, WeSupply helps you turn seasonal stock challenges into moments that build trust and loyalty.

👉 Ready to elevate your peak season game? Book a demo today!

Backorders and shipping delays are a natural part of peak season—but customer frustration doesn’t have to be. With the right strategy and tools in place, you can transform stock shortages into opportunities to build loyalty and strengthen your brand.

By combining accurate demand forecasting, strategic inventory planning, proactive communication, and seamless fulfillment, you can stay ahead of seasonal chaos. And with WeSupply by your side, mastering backorder management becomes easier than ever.

From real-time order tracking and automated backorder notifications, to carrier integrations with FedEx, UPS, and USPS, WeSupply helps you keep customers informed and confident throughout the entire post-purchase journey. Its self-service tracking portal, customizable backorder messaging, and in-depth analytics give your team the tools to reduce WISMO tickets, prevent cancellations, and deliver outstanding service—even when inventory runs low.

As the next peak season nears, remember: it’s not just about fulfilling orders—it’s about creating seamless, transparent, and trust-building experiences. With WeSupply, you can do both.

Keep your customers engaged during the delivery experience

Book a quick call with our experts to see how WeSupply can help you engage your customers with relevant updates through the right channel, at the right time.

Combat inconvenience with proactivity & self service

Book a quick call with our experts to see how WeSupply can help you make returns easy for your customers with a beautiful, self-service solution that makes their experience easier while also providing new ways to lower costs and earn back revenue.

1. What is the best way to manage backorders during peak seasons?

To manage backorders effectively, use accurate demand forecasting, set inventory reorder points, maintain strong supplier relationships, and communicate transparently with customers throughout the process.

2. How should you communicate stock delays to customers?

Be proactive and honest. Use email, SMS, website banners, and product page notices to inform customers of expected shipping timelines, causes of delays, and available alternatives.

3. Why do backorders increase during peak shopping seasons?

Backorders spike due to surging demand, limited supplier capacity, and supply chain slowdowns. Without proper forecasting and stock planning, popular items run out quickly during sales events.

4. How does WeSupply help manage backorders during peak seasons?

WeSupply provides real-time order and inventory updates, automated customer notifications, and detailed analytics, making it easier to keep customers informed and reduce support tickets.

5. Can WeSupply integrate with FedEx, UPS, and USPS to manage backorder shipments?

Yes! WeSupply integrates seamlessly with major carriers like FedEx, UPS, and USPS to provide accurate tracking—even for backordered or split shipments.

6. How does WeSupply reduce “Where is my order?” (WISMO) inquiries during backorder delays?

Through its self-service tracking portal and proactive notifications, WeSupply empowers customers to check order status anytime—reducing WISMO tickets and improving satisfaction.

7. Does WeSupply have an Official Shopify App?

Yes. WeSupply has an Official Shopify App. You can download it and start integrating with your Shopify Store.

8. Does WeSupply have an official Magento extension?

Yes, WeSupply has an official extension for Magento. The WeSupply x Magento integration allows for automating order tracking experiences, reducing customer inquiries, automating shipping email and SMS notifications, and providing a fully branded order tracking experience

9. Does WeSupply have an official BigCommerce App?

Yes, WeSupply has an official BigCommerce App. You can integrate WeSupply with your BigCommerce store to improve your post-purchase customer experience.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

Discover effective strategies to prevent return promo abuse with smart logic. Enhance your business’s integrity!

Learn how to effectively manage promo bundle returns while protecting your revenue. Discover practical tips to streamline your process!

Learn how to manage BOGO returns effectively while ensuring customers aren’t charged for the free item. Practical solutions!

Explore how automation and data can enhance your shipping strategy. Discover best practices to stay competitive and efficient. Read the article now!

Discover effective strategies to prevent return promo abuse with smart logic. Enhance your business’s integrity!

Learn how to effectively manage promo bundle returns while protecting your revenue. Discover practical tips to streamline your process!

Boost your revenue by turning returns into opportunities with personalized upsell offers. Discover effective strategies!

Discover 7 essential tips for implementing eco-friendly shipping practices that boost your brand’s sustainability!

Explore how automation and data can enhance your shipping strategy. Discover best practices to stay competitive and efficient. Read the article now!