RMA meaning, what it is, the process, use cases, and how to implement

In this post we’ll explore the RMA meaning, discussing what RMAs are, best practices for managing them effectively and more.

Boost customer experience and reduce support tickets

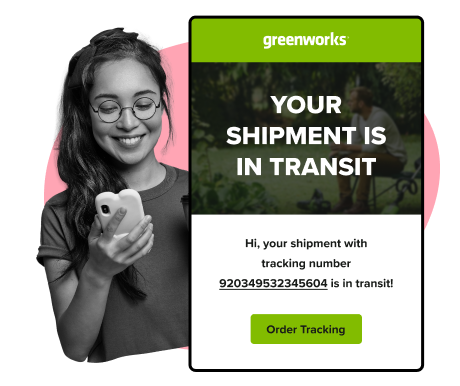

Realtime order and shipment tracking

Proactive order and shipping notifications

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

In the fast-paced world of eCommerce, businesses must constantly adapt to meet customer demand and stay ahead of the competition. One critical aspect of success in this industry is effective inventory allocation. Proper inventory management not only ensures products are available when customers need them but also helps optimize the supply chain and minimize costs. So, how can your eCommerce business harness the power of inventory allocation to unlock its full potential? Let’s dive in!

Inventory Allocation is essential for businesses operating across multiple channels to optimize operations, reduce risks and enhance customer satisfaction.

Automated systems offer increased accuracy, efficiency and reduced risk of human error compared to traditional manual inventory allocation methods.

Businesses must embrace change, leverage technology & implement strategic planning in order to remain successful in the ever-evolving world of eCommerce inventory allocation.

Using an automated post-purchase system, like WeSupply, is vital for efficient returns and inventory management. With features like product restocking and restocking fees, it minimizes the financial impact of returns, enhancing the post-purchase experience.

Inventory allocation is the lifeline of eCommerce, ensuring that products are available when and where customers need them. As businesses expand their sales channels and customer base, managing inventory becomes increasingly complex. A well-executed inventory allocation strategy helps businesses meet customer demand, manage their supply chain, and minimize costs.

This article will delve into different inventory allocation methods, their role in the eCommerce ecosystem, and the respective benefits and challenges of each.

In the world of eCommerce, inventory allocation is a crucial aspect that determines a business’s success. Efficient stock management is key in meeting customer demand and ensuring customer satisfaction. To optimize their operations, businesses need to adopt effective inventory allocation methods that consider factors such as demand, warehouse space, and storage costs.

An efficient inventory allocation strategy can help businesses lower the risk of overstocking or understocking, thereby preventing lost sales, escalated shipping costs, and decreased customer satisfaction. Embracing technology and automation can further streamline the process, allowing businesses to track inventory levels in real-time and make informed allocation decisions.

In essence, the benefits of inventory allocation play a vital role in creating a more efficient supply chain, ultimately leading to improved supply chain efficiency that benefits both businesses and their customers.

Inventory allocation refers to the practice of apportioning stock to fulfill customer orders, ensuring that businesses have the right products, in the right locations, at the right time. This process is crucial in the eCommerce ecosystem, as it impacts customer satisfaction and a business’s financial effectiveness.

With various inventory allocation methods available, a business needs to choose the most suitable one to optimize its operations. In this part, we’ll examine the meaning of inventory allocation, its role, and the various methods along with their respective advantages.

Inventory allocation refers to the practice of apportioning stock to fulfill customer orders, ensuring that businesses have the right products, in the right locations, at the right time. This process is crucial in the eCommerce ecosystem, as it impacts customer satisfaction and a business’s financial effectiveness.

Proper inventory allocation is key to streamlining order fulfillment and averting issues that may arise during the process, such as excess inventory or stockouts. By considering factors such as customer demand, warehouse space, and distribution network, businesses can optimize their inventory allocation, ultimately leading to a more efficient supply chain and enhanced customer satisfaction.

Different inventory allocation methods can be employed to optimize stock distribution and cater to varying business needs. Push allocation is based on historical and internal data to anticipate customer demand, while pull allocation relies on actual customer demand to validate shifting inventory.

The just-in-time (JIT) allocation method combines elements of both push and pull allocation, seeking to optimize inventory levels to meet customer demand while minimizing overstock. Each method has its advantages and drawbacks, and businesses must evaluate their specific requirements and market conditions to select the most suitable allocation method for their operations.

Inventory mismanagement can have far-reaching consequences on a business’s overall performance. Overstocking and understocking can result in increased costs, missed sales opportunities, and customer dissatisfaction.

We will address the dangers of inventory mismanagement in this part, specifically the impact of overstocking and understocking on multichannel sales. We will also explore how businesses can build a scalable foundation through smart inventory allocation, ensuring long-term success in a competitive market.

Overstocking and understocking are two major pitfalls that businesses must avoid in inventory management. Overstocking can lead to increased carrying and operating costs, as well as potential product expiry or difficulty in selling, ultimately resulting in financial losses.

On the other hand, understocking can cause customer dissatisfaction, missed sales opportunities, and decreased profitability. To mitigate these risks, businesses must adopt effective inventory allocation methods that optimize stock levels and cater to customer demand.

Inventory missteps can have a significant impact on multichannel sales and overall business performance. Inadequate inventory allocation can lead to overstocking or understocking, resulting in lost sales opportunities, increased costs, and diminished customer satisfaction.

Effective inventory allocation is crucial for businesses operating across multiple sales channels, as it ensures that products are available in the appropriate locations at the necessary times. By adopting efficient inventory allocation methods and leveraging technology, businesses can optimize their inventory management and minimize costs associated with inventory mismanagement.

Building a scalable business foundation through smart inventory allocation is essential for long-term success. By adopting best practices and leveraging technology, businesses can optimize their inventory allocation and ensure that products are available when and where customers need them. This not only helps to minimize the risk of overstocking or understocking but also enables businesses to:

Stay competitive in the ever-evolving eCommerce landscape

Improve customer satisfaction by reducing stockouts and backorders

Increase operational efficiency by streamlining inventory management processes

Maximize profitability by minimizing carrying costs and obsolescence

By implementing these strategies, businesses can build a strong foundation for growth and success.

Continuous improvement and adaptation of inventory allocation strategies are crucial for businesses to remain agile and responsive to market changes and customer demand.

Technology plays a pivotal role in inventory allocation, enabling businesses to automate processes, gather data, and make informed decisions. From traditional manual inventory allocation methods to automated systems, the use of technology has revolutionized the way businesses manage their inventory.

We’ll explore how technology aids inventory allocation in this part, discussing the benefits of automated systems, software solutions, and analytical tools that aid businesses in predicting and meeting customer demand more proficiently.

Traditional manual inventory allocation methods can be time-consuming and prone to errors. On the other hand, automated allocation systems offer several advantages:

They leverage technology to track, check, and update inventory in real time.

They provide increased accuracy and efficiency.

They reduce the risk of human error.

They save time and resources.

By implementing an automated inventory management system, businesses can streamline their inventory management processes and improve overall efficiency.

By automating inventory management processes, businesses can:

Save time and resources

Minimize the risk of overstocking or understocking

Ensure that products are available to customers when and where they need them

In today’s competitive eCommerce landscape, adopting automated allocation systems is crucial for businesses seeking to optimize their inventory allocation and stay ahead of the competition.

Various software solutions are available for automating inventory management, streamlining processes, and reducing errors. These solutions can help businesses track inventory levels in real-time, forecast customer demand, and optimize stock distribution across multiple locations and sales channels.

By leveraging software solutions, businesses can minimize the risk of overstocking or understocking, improve customer satisfaction, and ultimately increase sales and profits.

An efficient post-purchase software can revolutionize inventory management. WeSupply’s platform not only streamlines returns and exchanges but also simplifies restocking, turning challenges into opportunities. In eCommerce, optimizing restocking is vital. With WeSupply, this becomes an integrated part of the return process, freeing up resources for other essential business tasks.

Analytical tools are essential for predicting and meeting customer demand, helping businesses optimize their inventory allocation strategies. These tools can analyze customer data, identify trends and patterns, and forecast demand, enabling businesses to adjust their inventory allocation strategies accordingly.

By utilizing analytical tools, businesses can ensure they have the right products in the right locations at the right times, ultimately enhancing customer satisfaction and boosting sales.

Though inventory turnover analytics are crucial, integrating it with other essential business data is paramount. WeSupply offers a holistic view by providing extensive analytics on logistics, shipments, orders, and returns.

Returns management made easy for your team

Book a quick call with our experts to see how WeSupply can help you streamline your return management.

Inventory allocation is influenced by various factors, including:

Allocation rules

Influencing factors

Lead time

Handling seasonal shifts

Understanding these factors and their impact on inventory allocation is crucial for businesses seeking to optimize their operations and meet customer demand.

We’ll examine these factors and their impact on inventory allocation decisions in this part, offering insights into how businesses can enhance their inventory management practices.

Crafting allocation rules, such as First-In-First-Out (FIFO) and Last-In-First-Out (LIFO), is essential for effective inventory management. These rules determine the order in which inventory is sold, helping businesses optimize their inventory levels and minimize the risk of spoilage or obsolescence.

By selecting the most suitable allocation rule for their business, companies can ensure that their inventory is managed efficiently and meets customer demand.

Various factors influence inventory allocation decisions, including demand, warehouse space, and order fulfillment. Understanding these factors and their impact on inventory allocation is essential for businesses seeking to optimize their operations and meet customer demand.

By taking these factors into account, companies can better allocate their inventory, ensuring that they have the right products, in the right locations, at the right time, ultimately leading to improved customer satisfaction and increased sales.

Lead time, which is the period between when an order is placed and when it is received by the end user, is a crucial factor in inventory allocation decisions. Understanding lead time and its impact on inventory allocation can help businesses optimize their supply chain and ensure that products are available when and where customers need them.

By factoring in lead time when allocating inventory, businesses can minimize the risk of stockouts and overstocking, ultimately improving customer satisfaction and boosting sales.

Handling seasonal shifts and sudden market changes is a critical aspect of inventory allocation. Adapting inventory allocation strategies to accommodate these fluctuations helps businesses stay competitive and meet customer demand.

By analyzing historical data and forecasting future demand, businesses can adjust their inventory allocation strategies to address seasonal shifts and market changes, ensuring that they have the right products, in the right locations, at the right time.

Adopting best practices for inventory allocation is essential for businesses seeking to optimize their operations and meet customer demand. This part will cover best practices for optimal inventory allocation, including:

Data centralization

Automation adoption

Maintaining a safety stock balance

Customer segmentation

Leveraging post-purchase software such as WeSupply that allow you to restock your inventory where applicable in the event of product returns

By implementing these practices, businesses can optimize their inventory allocation, ensuring that products are available when and where customers need them, ultimately enhancing customer satisfaction and boosting sales.

Centralizing inventory data is crucial for efficient inventory management. By consolidating inventory data into a centralized inventory management system, businesses can improve visibility and control over their inventory levels, ensuring that products are available when and where customers need them.

Centralization helps businesses in the following ways:

Making more informed decisions about inventory allocation

Minimizing the risk of stockouts and overstocking

Improving customer satisfaction

Boosting sales

Embracing automation can streamline inventory allocation processes and reduce the risk of errors. One such example is the use of automatic reorder alerts, which notify businesses when inventory levels reach a predetermined threshold, allowing them to promptly restock their supplies.

By leveraging automation and automatic reorder alerts, businesses can optimize their inventory allocation, ensuring that products are available when and where customers need them, ultimately improving customer satisfaction and boosting sales.

Maintaining a safety stock balance is essential for ensuring that businesses have sufficient stock to accommodate unexpected demand fluctuations. Safety stock acts as a buffer against stockouts, helping businesses meet customer demand even in the face of unforeseen market changes.

By maintaining a safety stock balance, businesses can minimize the risk of stockouts and overstocking, ultimately improving customer satisfaction and boosting sales.

Customer segmentation allows businesses to:

Tailor their inventory allocation strategies to meet the unique needs and preferences of different customer groups

Segment customers based on factors such as location, demographics, and purchase behavior

Allocate inventory more efficiently, ensuring that the right products are available to the right customers at the right time.

This tailored approach to inventory allocation not only enhances customer satisfaction but also maximizes sales and profits.

Multi-channel inventory management presents a unique set of challenges for businesses, including capacity and demand dilemmas and the need to address returns.

We’ll discuss these challenges in this part and outline strategies to overcome them, ensuring efficient inventory management across various sales channels.

Managing capacity and demand in multi-channel inventory management can be a complex task, requiring strategic planning and efficient allocation. Balancing the quantity of inventory available with the quantity required to fulfill customer demand is essential for avoiding overstocking and understocking, which can result in lost sales opportunities, increased costs, and diminished customer satisfaction.

By employing effective inventory allocation methods and leveraging technology, businesses can overcome capacity and demand dilemmas and optimize their inventory management across multiple channels.

Returns can have a significant impact on stock levels and inventory management, making it crucial for businesses to address them effectively. A well-established returns policy, regular monitoring of returns data, and the use of analytics to identify patterns in returns are essential for managing returns and maintaining efficient inventory allocation.

By implementing these strategies, businesses can minimize the impact of returns on their stock levels and ensure that they have the right products available to meet customer demand.

Partnering with a third-party logistics (3PL) provider for inventory allocation can offer numerous benefits, including streamlined processes and access to expert insights.

We’ll discuss the benefits of collaborating with a 3PL for inventory allocation in this part and how it aids businesses in optimizing their inventory management processes, thereby enhancing overall performance.

By partnering with a 3PL for inventory allocation, businesses can:

Streamline processes

Gain access to specialist optimization expertise

Monitor inventory levels

Forecast customer demand

Optimize stock distribution across multiple distribution centers and sales channels.

With their expertise and resources, 3PLs can assist businesses in overcoming challenges associated with inventory allocation and management, ultimately improving customer satisfaction, increasing sales, and reducing costs.

Effective inventory allocation is the key to success in the competitive world of eCommerce. Businesses can optimize their inventory allocation processes, meet customer demand, and streamline their supply chain by embracing change, technology, and strategic planning.

As the eCommerce landscape continues to evolve, businesses must remain agile and responsive to market changes and customer needs. By adopting best practices, leveraging technology, and embracing innovation, businesses can thrive and achieve growth in the world of eCommerce inventory allocation.

As the eCommerce industry continues to grow and evolve, so too will the need for effective inventory allocation strategies. Businesses must remain agile and responsive to market changes and customer demand, constantly adapting and improving their inventory allocation processes.

By embracing change, technology, and strategic planning, businesses can ensure their ongoing success in the competitive world of eCommerce inventory allocation.

In conclusion, embracing change, technology, and strategic planning is essential for businesses looking to optimize their inventory allocation processes and achieve growth in the eCommerce sector. By adopting best practices, leveraging technology, and staying ahead of market trends, businesses can remain competitive, meet customer demand, and ultimately achieve success in the world of eCommerce inventory allocation.

In summary, effective inventory allocation is critical for eCommerce businesses looking to optimize their operations, meet customer demand, and stay ahead of the competition. By adopting best practices, leveraging technology, and embracing change, businesses can ensure their ongoing success in the ever-evolving landscape of eCommerce inventory allocation. With the right strategies in place, businesses can thrive and achieve growth in this competitive industry.

Product Allocation is a strategic inventory method used to manage limited quantities of products across distribution networks and sales channels. This allows the available inventory to be distributed to meet customer demand as effectively as possible. By using Product Allocation, businesses can ensure that their products are being distributed to the right channels and customers, while also maximizing their profits. This method can also help businesses to reduce their inventory costs.

Inventory allocation is important for businesses of all sizes to ensure efficient operations, accurate reporting, and optimized supply chain. It helps keep track of inventory levels, determine the exact prices, and avoid under and overstocking to reduce storage expenses. By allocating inventory properly, businesses can ensure that they have the right amount of stock on hand to meet customer demand. This helps to reduce the risk of stockouts and improve customer satisfaction.

In logistics, allocation is the process of inspecting and storing goods in inventory to facilitate picking and shipping.

Soft inventory allocation allows for more flexibility as it commits the supply to customer demand but still leaves room for adjustments if needed.

Inventory allocation is essential for eCommerce businesses, as it enables efficient inventory fulfillment to meet customer demand and optimize the supply chain while reducing costs.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

In this post we’ll explore the RMA meaning, discussing what RMAs are, best practices for managing them effectively and more.

In this post, we’ll explore the latest in package tracking solutions, the importance of customer trust, and how businesses can prepare for the holiday rush.

In this post, we’ll explore the importance of ending inventory and practical examples to help you gain a deeper understanding of this essential concept.

In this post, we’ll delve into the current state of warranty management and provide practical tips to enhance the warranty claims process.

Let’s dive into the challenges, opportunities, and best practices that will help you navigate the world of shipping and ensure your packages arrive on time.

We will walk you through the process of calculating inventory turnover and provide you with actionable strategies to improve your inventory management.

In this blog post, we’ll guide you through the secrets of successful parcel contract negotiation and how to overcome common challenges.

Shipping costs impact your business. Let’s explore how to accurately calculate shipping costs to boost sales and customer satisfaction.

In this guide, we’re going to help you understand how to work out your return rate and how to improve your returns process to increase profits.