Maximize Efficiency in Bulk Returns Handling: Essential Strategies

Discover essential strategies to streamline bulk returns handling and enhance efficiency. Read the article for practical tips!

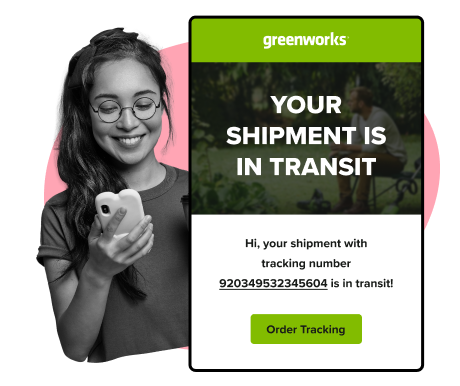

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

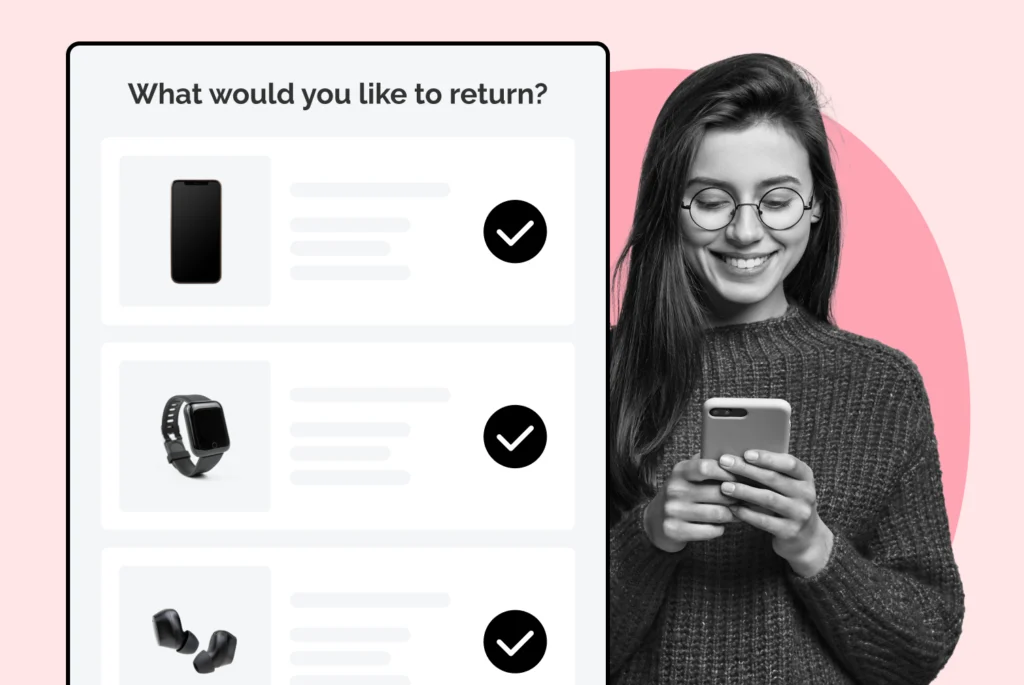

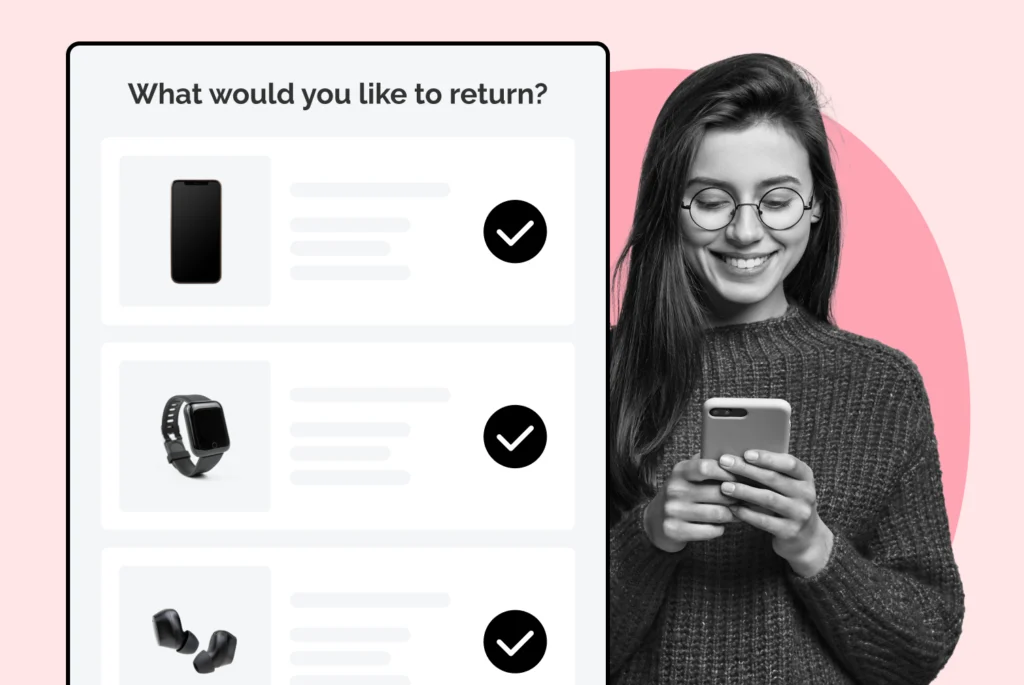

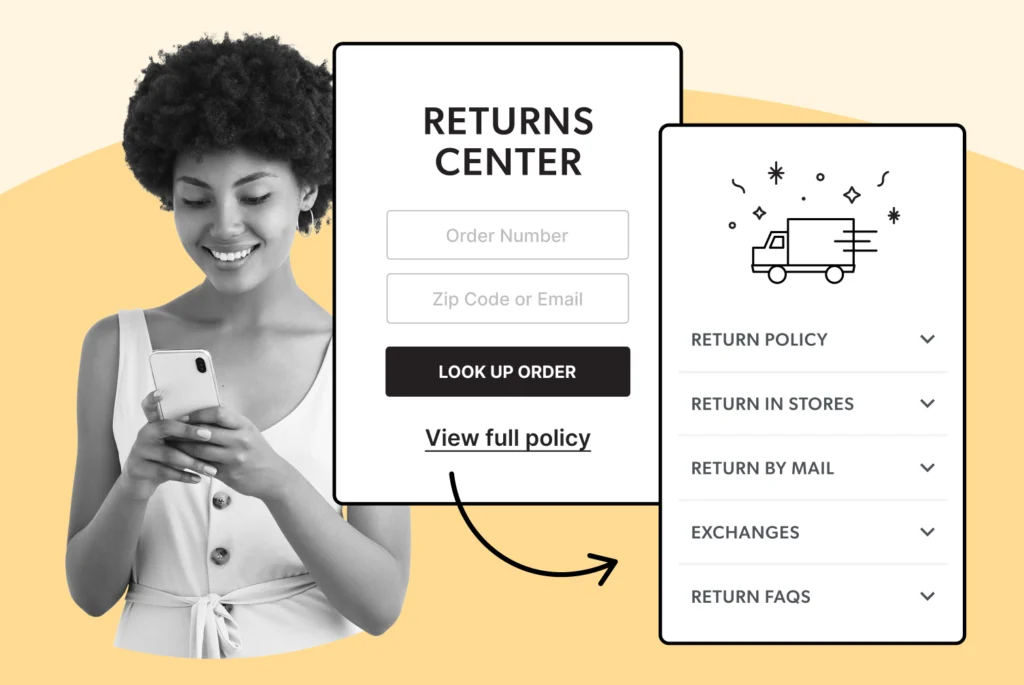

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Easy claims and smart upsells

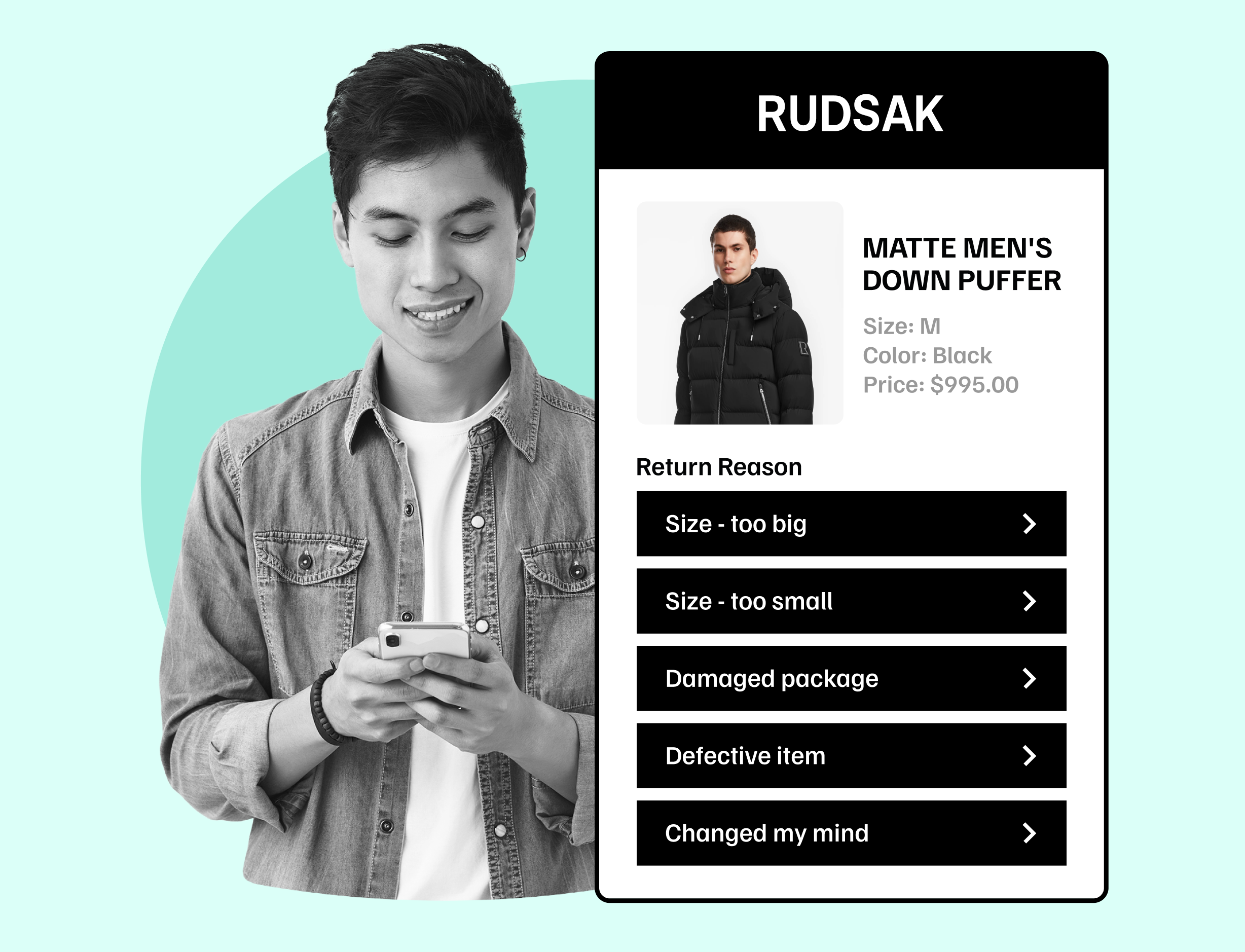

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

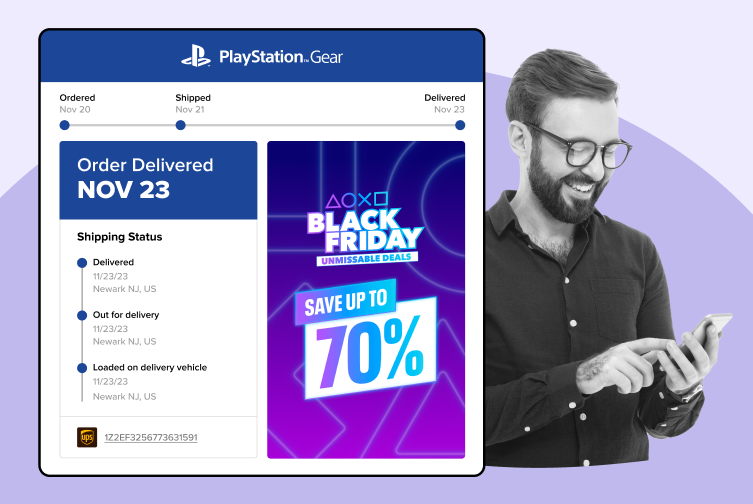

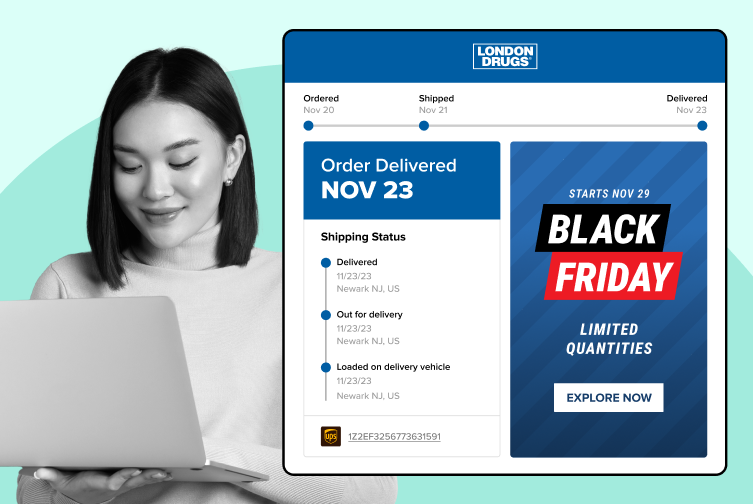

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Equip your team for precise return checks.

Easy claims and smart upsells

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

Every enterprise that sells products faces the same challenge: what happens when customers return items? Returns are unavoidable in business, but how you manage them can determine whether they become a costly burden or a strategic advantage. Reverse logistics, the process of moving goods from customers back to suppliers or manufacturers, plays a central role in this equation.

Understanding reverse logistics is essential for modern supply chain management, as it differs from traditional logistics by focusing on returns management and its impact on customer satisfaction.

For enterprises, streamlining reverse logistics is not just about reducing costs. It is about improving customer loyalty, protecting brand reputation, and recovering value from returned goods. Poorly managed returns cost retailers billions each year, while efficient systems can reduce expenses, drive sustainability, and even generate new revenue streams.

This guide will walk you through proven strategies to streamline enterprise reverse logistics, from policy design and technology adoption to sustainability and performance tracking.

Logistics has two sides. Forward logistics, often referred to as traditional logistics, covers the movement of goods from suppliers to customers. Reverse logistics handles the opposite direction returns, repairs, refurbishments, recycling, and resale, involving the reverse flow of products from customers back to the origin.

In many enterprises, forward logistics is highly optimized, while reverse logistics lags behind. This imbalance creates inefficiencies, costs, and customer frustration. To create a truly resilient supply chain, enterprises must treat reverse logistics with the same level of attention and investment as forward logistics.

The scale of returns in enterprise retail is staggering. According to the National Retail Federation, U.S. retailers received $743 billion in returned merchandise in 2023, representing 16.5% of all retail sales. Each return is more than just a refund it involves shipping, inspection, processing, and sometimes disposal.

When reverse logistics is poorly managed, enterprises face:

Excess transportation and labor costs.

Inventory disruptions that hurt product availability.

Lost opportunities to recover or resell returned goods.

Declining customer trust from slow or confusing return processes, which can increase customer concerns about the reliability and responsiveness of the business.

Streamlining these processes can turn losses into opportunities for efficiency and revenue recovery.

Reverse logistics has several moving parts, but three stand out as foundational:

Inventory Management: Enterprises must track returned goods carefully to avoid losses and maximize recovery. Poor tracking often leads to write-offs that could have been avoided.

Customer Satisfaction: The returns process is often the last direct interaction with a customer. A seamless experience boosts loyalty, while a frustrating one can drive customers away.

Return Policies: Clear and fair policies set expectations upfront, reducing disputes, confusion, and unauthorized returns.

Getting these basics right creates a strong foundation for everything else.

Optimization begins with process design. Efficient reverse logistics is essential for reducing costs and improving customer satisfaction. Enterprises can improve reverse logistics by ensuring efficient returns processes to streamline operations and maintain an efficient flow of goods throughout both forward and reverse logistics:

Centralized return center: Consolidating returns into a centralized return center speeds up sorting and reduces bottlenecks. Maintaining an efficient flow of goods in both directions is critical for timely deliveries and cost reduction.

Efficient return shipping labels: Prepaid labels or digital QR codes simplify the process for customers and reduce administrative work.

Stronger inventory management: Enterprises need real-time visibility into returned goods to avoid unnecessary write-offs.

At the same time, processes must prioritize customer convenience. A rigid or confusing return experience might lower costs in the short term but will cost more in customer lifetime value.

Technology is the backbone of modern reverse logistics. Enterprises that rely on manual or spreadsheet-driven processes cannot handle the volume and complexity of today’s returns.

Key technologies include:

Returns Management Systems (RMS): These platforms automate RMAs, generate labels, and track returns across their lifecycle. Enterprises that implement RMS often see faster turnaround times and fewer errors.

Automation and AI: Automated sorting equipment reduces labor needs. AI can detect fraud by analyzing suspicious return patterns and assist in triaging returned items.

Barcode and RFID tracking: These tools provide item-level visibility, reducing losses and ensuring products are routed correctly.

Data analytics: By analyzing return reasons and trends, enterprises can identify product defects, sizing issues, or misleading descriptions that drive unnecessary returns.

A reverse logistics expert can help enterprises implement and optimize these technologies, ensuring process improvements, cost savings, and alignment with business goals.

McKinsey reports that companies using advanced analytics in reverse logistics can cut costs by 15–25% while also improving customer satisfaction.

Centralized returns hubs, often referred to as a centralized processing center, give enterprises tighter control over returned goods. They simplify logistics, reduce transportation costs, and enable faster decision-making about whether items should be restocked, refurbished, or recycled. The distribution center plays a crucial role in the reverse logistics process by centralizing the handling and disposition of returned merchandise to improve efficiency and accuracy.

Collaboration is equally important. Enterprises that coordinate closely with suppliers and logistics partners gain efficiencies across the supply chain. Third-party logistics providers (3PLs) specializing in reverse logistics can often process returns more cost-effectively than in-house teams, especially at scale.

Forward and reverse logistics should also be integrated. Combining flows such as backhauling returned items on trucks delivering new products can reduce transportation costs and emissions.

One of the biggest opportunities in reverse logistics is turning returned goods into revenue instead of losses. Enterprises can do this through:

Restocking and refurbishing: Items in good condition can be resold as new. Lightly used or defective items can be refurbished and resold at a discount.

Re-commerce and secondary markets: Selling open-box or refurbished products on specialized secondary markets recaptures value while appealing to bargain-seeking customers.

Return-to-vendor programs: Defective items can be sent back to manufacturers for credit or replacement.

Recycling and responsible disposal: Even items beyond repair can yield value through material recovery, including the extraction of valuable materials for reuse in new products.

Offering store credit as an alternative to refunds can help retain revenue and provide a customer-friendly return experience.

According to Optoro, recommerce and resale strategies can help retailers recover up to 80% of an item’s original value, compared to much lower recovery through liquidation or disposal.

Reverse logistics is a cornerstone of the circular economy, which aims to minimize waste and keep products in use for as long as possible. Recycling programs play a crucial role in supporting the circular economy by enabling the recovery and reuse of materials from returned products.

By refurbishing, reusing, and recycling returned goods, enterprises not only reduce environmental impact but also enable more sustainable practices throughout their operations. These actions provide significant environmental benefits, such as reducing waste, conserving resources, and lowering carbon emissions, while also aligning with growing consumer demand for sustainability. In fact, a 2023 Nielsen survey found that 78% of consumers say sustainability influences their purchasing decisions.

Embedding circular practices in reverse logistics helps enterprises strengthen brand reputation while reducing waste and costs.

Sustainability is no longer optional it is a competitive advantage. Enterprises can integrate sustainable practices into reverse logistics by:

Using recyclable and eco-friendly packaging.

Minimizing packaging waste through smarter design.

Consolidating shipments to reduce carbon emissions.

Partnering with recycling and upcycling programs for returned goods.

Implementing efficient reverse logistics processes to reduce waste by optimizing returns, repairs, recycling, and disposal.

These efforts not only reduce environmental impact but also improve efficiency by cutting unnecessary material and transportation costs.

Make reverse logistics sustainable & cost-efficient

Book a quick call with our experts to see how WeSupply helps you adopt eco-friendly packaging, reduce waste, consolidate shipments, and manage recycling or repairs through efficient processes that cut costs while lowering environmental impact.

Packaging plays an often-overlooked role in reverse logistics. Poorly designed packaging increases damage rates and complicates returns. Effective packaging is also crucial in the order fulfillment process, as it ensures products are protected during transportation and supports efficient delivery to customers, while facilitating smoother reverse logistics operations.

By designing packaging with reverse logistics in mind using durable, reusable, or recyclable materials enterprises can:

Reduce product damage and returns caused by shipping.

Simplify recycling or reuse of packaging materials.

Improve customer satisfaction with eco-friendly packaging options.

Smart packaging design contributes to both cost reduction and sustainability.

Customer expectations around returns are higher than ever. Enterprises must balance cost efficiency with convenience. Handling return requests efficiently is crucial, and having a flexible returns process ensures customers can initiate returns easily, improving their overall experience.

By analyzing return data and gathering customer feedback, businesses can better understand why products are returned and adjust policies, product descriptions, or sizing information accordingly. Understanding return reasons is also key to retaining customers, as it allows companies to address issues and improve customer loyalty. Transparent communication such as clear return policies and tracking updates helps build trust and loyalty.

Simplify Returns for Your Customers and Support Team

Book a quick call with our experts to see how WeSupply can help you: simplify the Return experience with just a few clicks, reduce customer service calls and manual processing, notify your customer about their refund, automate returns and reduce user error.

Delivery failures, such as undeliverable or rejected items where the delivery failed due to unforeseen circumstances, are a hidden but significant part of reverse logistics. Enterprises must have efficient processes for handling these cases.

Centralized return centers and strong inventory management help minimize losses from delivery failures. Enterprises can also integrate delivery failure management with broader reverse logistics strategies to recover value quickly and maintain customer satisfaction.

You cannot improve what you do not measure. Enterprises must track key performance indicators (KPIs) to optimize reverse logistics and assess the effectiveness of their reverse logistics work, identifying areas for improvement.

Important metrics include:

Return rates.

Average processing time.

Recovery value per return.

Cost per return.

Customer satisfaction scores.

AI-driven analytics can provide predictive insights, such as forecasting return volumes or identifying emerging product issues. An optimized reverse logistics system delivers benefits like reduced costs, increased efficiency, and better supply chain visibility. Creating an efficient reverse logistics process is crucial to minimize costs and improve outcomes. Regular audits and continuous improvement initiatives ensure returns stay under control.

Technology and processes alone are not enough. Enterprises must also invest in people. Training employees on reverse logistics systems, sustainability practices, and customer-first approaches ensures consistent execution. Reverse logistics encompasses a wide variety of tasks and knowledge areas, including returns management, refurbishment, recycling, and disposal, so staff must be equipped to handle each step effectively.

Equally important is building a culture that views reverse logistics as a strategic asset, not just a cost center. When teams see returns as opportunities for learning, revenue recovery, and sustainability, outcomes improve across the board.

Free returns are now a customer expectation in many industries. While they can be expensive, they also drive loyalty and repeat purchases, increasing the likelihood of repeat business as customers are encouraged to make additional purchases.

The key is to offer free returns strategically balancing customer satisfaction with cost control. Technology, data analytics, and strong partnerships can make free returns feasible without undermining profitability.

Enterprises face recurring challenges in reverse logistics: managing returns is a key challenge that requires strategic planning and operational efficiency. Enterprises must also navigate different types of reverse logistics, such as product returns, remanufacturing, recycling, and disposal, each presenting unique complexities. The reverse supply chain is an important aspect of handling returns and exchanges, ensuring that products move efficiently back through the logistics system. Reverse logistics involves coordinating activities like product collection, inspection, sorting, and restocking to address these challenges effectively. Integrated supply chain reverse logistics strategies are essential for seamless coordination between forward and reverse flows, optimizing resources and maintaining customer satisfaction.

High return volumes in e-commerce.

Regulatory compliance for disposal and recycling.

Scalability when introducing new systems.

The solution is to start small launch pilot programs for new tools or processes, measure outcomes, and then scale. Optimizing the supply chain process to handle returns efficiently is crucial for reducing costs and improving performance. Automated documentation and compliance tools also reduce regulatory risks. By adopting modern solutions, enterprises can turn reverse logistics into a strategic advantage, transforming returns management into a driver of business growth and customer loyalty.

Implementing best practices in reverse logistics is essential for enterprises aiming to optimize their supply chain and deliver superior customer satisfaction. Start by establishing a clear, flexible return policy that outlines every step of the return process, including the use of return merchandise authorization (RMA) systems and offering free return shipping where feasible. This transparency not only streamlines the backward movement of goods but also builds customer loyalty and trust, reducing the risk of customer dissatisfaction and negative feedback.

Investing in advanced inventory management systems is another critical best practice. These systems enable real-time tracking of returned products, ensuring that items are quickly restocked, refurbished, or responsibly disposed of. Efficient inventory management reduces operational costs, minimizes shipping costs, and helps prevent unnecessary waste.

Additionally, enterprises should regularly review and refine their reverse logistics operations to identify bottlenecks and opportunities for improvement. By focusing on reducing waste, lowering costs, and enhancing the overall return process, businesses can strengthen their brand reputation and foster long-term customer loyalty. Ultimately, a well-executed reverse logistics strategy not only optimizes supply chain management but also turns returns into a source of business value.

As ecommerce continues to expand, enterprises face increasing complexity in managing reverse logistics operations on a global scale. Online purchases often result in higher return rates compared to in-store purchases, making it crucial for businesses to develop robust strategies for handling international returns. This involves navigating diverse regulatory compliance requirements, understanding cultural differences, and meeting varying customer expectations across regions.

Global reverse logistics processes require careful management of raw materials, packaging, and shipping costs to ensure efficient and cost-effective returns. By implementing standardized yet adaptable reverse logistics operations, companies can minimize waste, reduce costs, and enhance customer satisfaction worldwide. Collaboration with recycling companies and delivery providers is essential for responsible disposal and to minimize the environmental impact of returned goods.

Moreover, a global approach to reverse logistics supports the circular economy by promoting the reuse and recycling of products and materials. Enterprises that manage reverse logistics effectively on an international scale not only comply with local regulations but also contribute to more sustainable business practices, reinforcing their commitment to environmental responsibility and operational excellence.

Reverse logistics is increasingly recognized as a strategic differentiator in supply chain commerce. By optimizing the return process and focusing on customer satisfaction, enterprises can gain a significant competitive edge. Leveraging technology such as data analytics, automation, and advanced reverse logistics management systems enables companies to streamline reverse logistics operations, reduce costs, and boost operational efficiency.

A well-designed reverse logistics system provides valuable insights into customer behavior and product performance, allowing businesses to refine their supply chain processes and address issues proactively. Effective reverse logistics management not only reduces waste and operational costs but also supports sustainability initiatives, minimizing environmental impact and enhancing brand reputation.

Prioritizing reverse logistics within the broader supply chain strategy helps build customer loyalty, as customers appreciate hassle-free returns and responsible business practices. By turning reverse logistics into a core competency, enterprises can drive growth, improve customer retention, and position themselves as leaders in both operational efficiency and environmental stewardship.

The benefits of streamlined reverse logistics are clear:

Enterprises can reduce costs by 20–30% through optimization.

Sustainability efforts cut waste and improve brand perception.

Customer satisfaction rises, leading to greater loyalty and retention; in fact, improved reverse logistics processes can significantly enhance brand loyalty by providing seamless return experiences.

Enterprises recover more value from returned goods through recommerce and recycling.

While outbound logistics focuses on delivering finished goods efficiently to customers, optimizing reverse logistics is equally important for overall supply chain performance and customer satisfaction.

Reverse logistics is no longer a back-office function. Done right, it is a source of competitive advantage that strengthens both the bottom line and customer relationships.

Handling enterprise returns can be tough, but WeSupply makes reverse logistics simple, efficient, and customer-friendly. By automating key steps and giving you full control, WeSupply helps reduce costs, speed up refunds, and improve customer satisfaction.

Here’s how:

✅ Flexible Return Rules – Set smart conditions, like free return shipping or item-specific policies, so each product follows the right path.

With WeSupply, enterprise reverse logistics turns from a challenge into an opportunity to save money, protect the planet, and keep customers coming back.

Book a demo today and see how WeSupply makes reverse logistics faster, smarter, and easier for your business.

Reverse logistics is complex, but WeSupply makes it manageable and profitable. With flexible return rules, self-service returns, QR code labels, and automated workflows, you save time and reduce errors.

Intelligent dispositions route items to the right destination, while in-store and international returns give customers more choice. Green return options like “keep the item” reduce waste, and analytics with CSAT, NPS, and CES tracking reveal why products come back and how to improve.

By streamlining returns with WeSupply, enterprises lower costs, speed up refunds, protect the planet, and strengthen customer loyalty all while turning reverse logistics into a driver of growth.

1. Why is reverse logistics important for enterprises?

Reverse logistics reduces costs, supports sustainability, and increases customer loyalty. Efficient returns management prevents inventory loss, speeds refunds, and improves brand reputation. Poorly managed systems cost enterprises billions annually.

2. How can enterprises reduce reverse logistics costs?

Enterprises reduce costs with centralized returns centers, prepaid or QR return labels, automation, and analytics. Optimizing inventory tracking and collaborating with 3PL providers can cut expenses by up to 30%.

3. How do enterprises recover value from returns?

Value is recovered through restocking, refurbishment, recommerce, secondary markets, vendor returns, or recycling. These methods maximize revenue recovery and reduce waste. Some enterprises recover up to 80% of value using recommerce strategies.

4. How does WeSupply streamline enterprise returns?

WeSupply automates return approvals, offers self-service portals, QR code labels, and in-store drop-offs. This reduces manual work, lowers costs, speeds refunds, and enhances customer satisfaction.

5. Can WeSupply handle international returns?

Yes. WeSupply lets you apply country-specific rules, including fees or restrictions. This flexibility ensures compliance and efficient handling of global enterprise returns.

6. What analytics does WeSupply provide for returns?

WeSupply tracks return reasons, product issues, and serial returners. It also measures CSAT, NPS, and CES to improve products, policies, and customer loyalty.

7. Does WeSupply have an Official Shopify App?

Yes. WeSupply has an Official Shopify App. You can download it and start integrating with your Shopify Store.

8. Does WeSupply have an official Magento extension?

Yes, WeSupply has an official extension for Magento. The WeSupply x Magento integration allows for automating order tracking experiences, reducing customer inquiries, automating shipping email and SMS notifications, and providing a fully branded order tracking experience.

9. Does WeSupply have an official BigCommerce App?

Yes, WeSupply has an official BigCommerce App. You can integrate WeSupply with your BigCommerce store to improve your post-purchase customer experience.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

Discover essential strategies to streamline bulk returns handling and enhance efficiency. Read the article for practical tips!

Discover proven best practices for designing an enterprise ecommerce returns policy that boosts customer satisfaction and long-term success.

Discover effective strategies for managing returns in retail. Enhance customer satisfaction while minimizing costs. Read the article for practical insights.

Learn effective strategies for handling shipping exceptions and keeping customers informed. Enhance your shipping process today!

Discover practical strategies to reduce shipping costs for your business. Boost your bottom line without sacrificing service. Read the article now!

Boost your average order value with effective upselling strategies post-purchase. Discover practical tips to enhance customer satisfaction. Read more!

Discover effective strategies to enhance ecommerce revenue retention and foster customer loyalty. Read the article to elevate your business success.

Discover how to analyze returns data to reduce return rates and boost profitability. Learn effective strategies to enhance your business’s performance.

Discover effective methods for analyzing customer feedback post-purchase. Enhance satisfaction and drive improvement!