What is cross-docking? What does cross-docking mean?

In this comprehensive guide, we’ll delve into the concept of cross-docking and explore its history, benefits, challenges, and best practices.

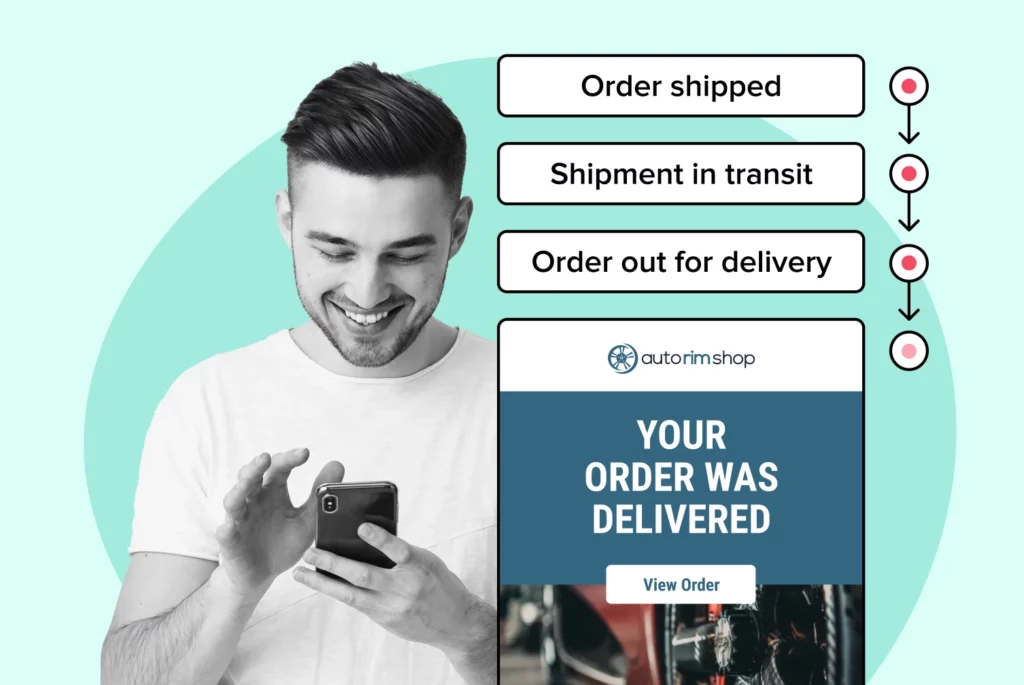

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

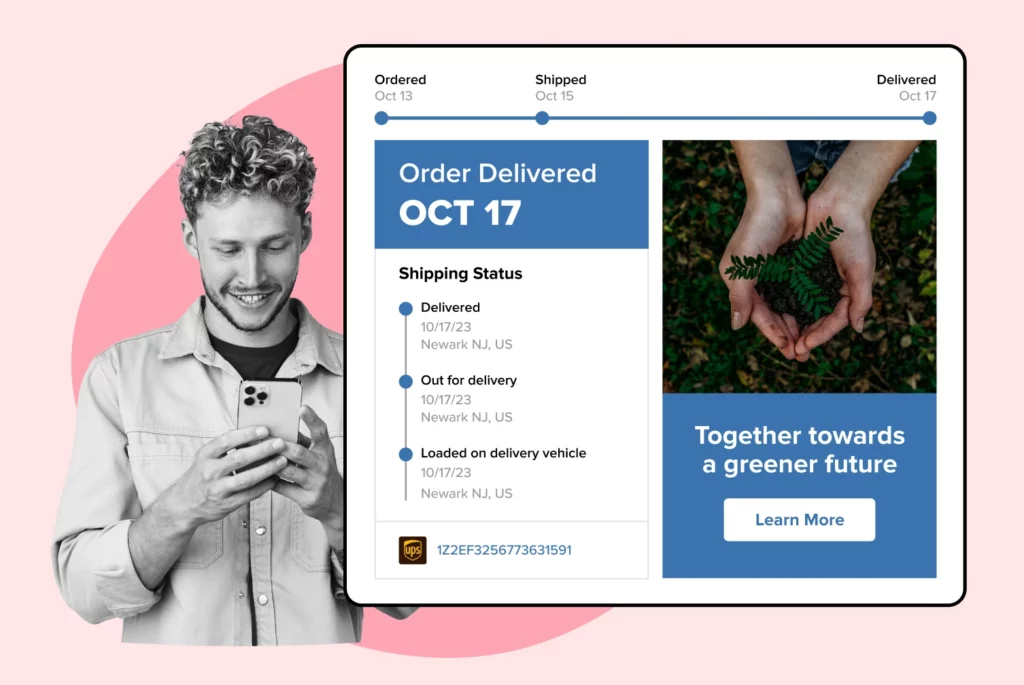

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

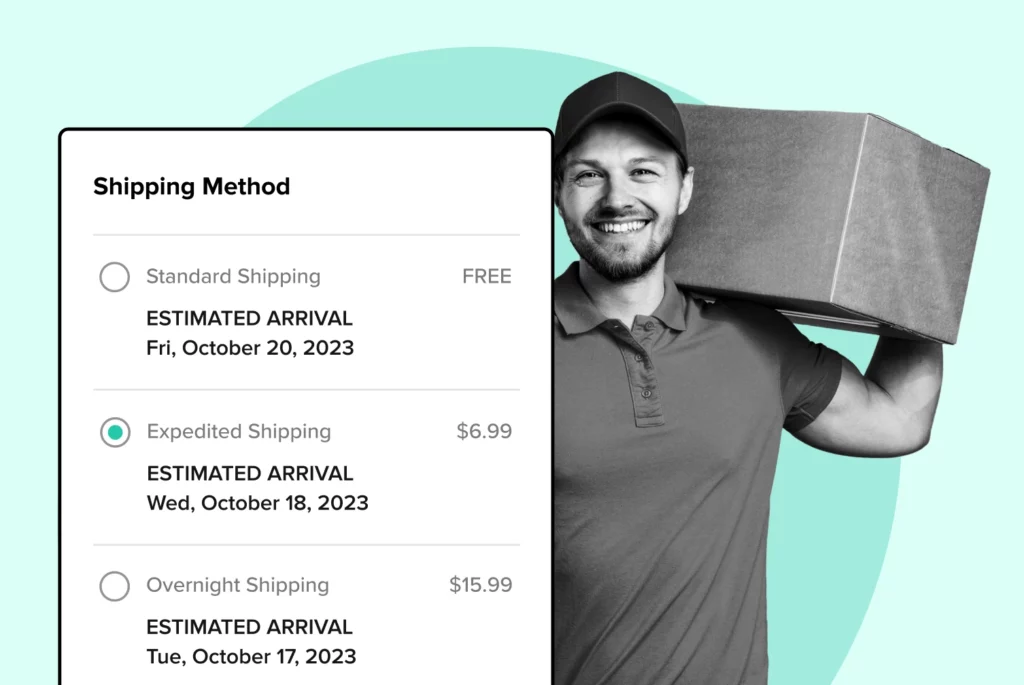

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Easy claims and smart upsells

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Shipping, Tracking & Notifications

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Identify and Resolve Order Issues

Realtime order and shipment tracking

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Returns management made easy for your team

Understand why your customers are returning

In-Store & Curbside Pickup

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Boost customer experience and reduce support tickets

Realtime order and shipment tracking

Proactive order and shipping notifications

AI-Enhanced Discounted Labels

Predictive pre-purchase estimated delivery dates

Self-Serivce branded order tracking

Effortless experience delivered

Make returns profitable and delight customers

Flexibility to define any return destinations & conditions

Simplify returns for your customers and team

Incentivize exchanges over returns

Returns management made easy for your team

Equip your team for precise return checks.

Easy claims and smart upsells

Understand why your customers are returning

Unify the online and the in-store experience

Hassle-free pickup experience for customers

In-Store Dashboard to keep operations streamlined

In-Store and Online orders unified

Drive foot-traffic to your stores

Find the answer to all your questions

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Find the answer to all your questions

Explore the most comon questions about WeSupply

Calculate the ROI that WeSupply can bring you

Request a no strings attached review of your current shopping experience and missed conversion opportunities

Take a step by step trip through our functionality to see how we can improve your ecommerce processes.

Read actionable articles on how to optimize your post-purchase experience and decrease support tickets

Get inspired by stories of how our customers implemented an effortless post-purchase experience

A Deep Dive into Top Companies' Order Tracking & Returns Strategy

Wondering if WeSupply is a good fit for you? Read through our use cases to see how we can help you increase conversion & improve CX!

eCommerce has seen exponential growth in recent years, and with this rapid expansion comes the need for efficient and effective order fulfillment processes. One critical aspect of eCommerce fulfillment is the pick and pack process, also known as “pick and pack ecommerce fulfillment”. This blog post will delve into the intricacies of pick and pack ecommerce fulfillment, discussing its importance, various strategies and optimization techniques, challenges faced, and future trends. By the end of this post, you’ll have a comprehensive understanding of the pick and pack process and its role in ensuring customer satisfaction and overall eCommerce success.

Pick and pack fulfillment is a crucial part of eCommerce order fulfillment, requiring businesses to employ strategies for successful operations.

Businesses must understand the scope, importance and core concepts of pick and pack in order to bridge customer expectations with efficient delivery.

Optimizing warehouse layout, leveraging technology integration, utilizing advanced picking techniques are essential components for successful pick and pack services that lead to increased customer loyalty.

Although Pick and Pack Fulfillment plays a crucial role in eCommerce dynamics, leveraging post-purchase optimization tools such as WeSupply can elevate your operations. WeSupply facilitates seamless access to real-time order and shipment tracking, consistent updates on order status, pre-purchase delivery date estimates, and connectivity with a broad spectrum of international carriers. Such comprehensive service enhances customer communication and satisfaction during their entire shopping journey.

Pick and pack fulfillment is a crucial aspect of eCommerce pack order fulfillment and involves picking individual items from inventory and packing them into designated boxes for shipment. This process requires efficient warehouse management and optimized operations to ensure customer satisfaction.

This part explores the pick and pack process, highlighting its significance, core concepts, and prepares the ground for a deeper understanding of this critical aspect of eCommerce fulfillment.

Pick and pack is a vital cog in the eCommerce order fulfillment machine, transforming inventory into parcels ready for shipment. The process comprises essential components such as order picking, cartonization, kitting, packaging, and the inclusion of a packing slip. Several strategies and optimization techniques can be employed to enhance the efficiency and accuracy of pick and pack operations, such as the pack method, partnering with a third-party logistics (3PL) provider, and utilizing order picking software.

With the steady growth of eCommerce, the significance of pick and pack fulfillment escalates, requiring businesses to adjust to emerging challenges and technologies to stay competitive.

Pick and pack fulfillment plays a critical role in eCommerce, as it streamlines the order fulfillment process and allows businesses to remain competitive in the market. An efficient fulfillment warehouse receiving process is essential for avoiding stock control difficulties and heightened operational expenses. Warehouse shelves, management systems (WMS), and inventory storage systems are crucial for storing, managing, and tracking inventory.

By understanding the scope, importance, and core concepts of pick and pack, businesses can better navigate the challenges and complexities of eCommerce fulfillment.

Pick and pack is not just a necessity for eCommerce businesses; it is the linchpin that connects customer expectations and efficient delivery. As customers increasingly demand faster and more accurate deliveries, businesses must optimize their pick and pack processes to meet these expectations and remain competitive.

This section delves into the significance of pick and pack fulfillment in eCommerce. It examines its role in bridging the gap between customer expectations and efficient delivery, and highlights the importance of inventory management and streamlined operations.

The pick and pack process, also known as the pick and pack method, is integral to maintaining customer satisfaction, as it optimizes, streamlines, and guarantees accurate delivery. Employing various picking strategies such as batch picking, zone picking, and wave picking can improve efficiency and reduce errors.

By ensuring that orders are accurately picked, packed, and shipped in a timely manner, businesses can bridge the gap between customer expectations and efficient delivery, resulting in increased customer loyalty and a competitive edge in the eCommerce market.

Furthermore, employing post-purchase platforms like WeSupply can elevate the customer journey by refining all elements following the order placement. WeSupply ensures precise, real-time order tracking, sends timely shipping alerts, and offers the option to establish a Self-Service Returns & Exchanges hub, making your returns procedure more efficient and user-friendly, thereby amplifying customer satisfaction.

Answer the #1 Customer Service Question: Where is My Order?

Book a quick call with our experts to see how WeSupply can help you give customers the ability to track their orders on your website to decrease the number of WISMO support tickets.

Effective inventory management and streamlined operations are crucial to the success of any pick and pack fulfillment process. By managing inventory accurately and implementing advanced warehouse management software, businesses can:

Reduce the likelihood of errors and delays in the order fulfillment process

Access discounts from shipping carriers

Identify the most cost-effective methods for delivering orders to customers

For example, WeSupply’s Intelligent Dispositions facilitate the automatic redirection of returned products to the appropriate warehouses, eliminating manual handling. In addition, WeSupply enables the option to restock returns directly within the return flow, further reducing the necessity for subsequent manual tasks.

Furthermore, working with an experienced 3PL partner can help businesses achieve these goals and optimize their pick and pack fulfillment process.

In essence, inventory management and streamlined operations are the lifeblood of successful pick and pack fulfillment.

This section provides a detailed explanation of the pick and pack process, offering a comprehensive understanding of how orders are received, picked, packed, and shipped. By understanding the inner workings of the pick and pack process, businesses can optimize their operations and ensure that they are meeting customer expectations and delivering orders accurately and efficiently.

The pick and pack process consists of several essential components, including:

Order receiving

Picking

Packing

Shipping

Each of these components plays a crucial role in ensuring that orders are fulfilled accurately and in a timely manner. When an order is received, the warehouse team is responsible for selecting the appropriate items from inventory and packing them into designated boxes. Throughout this process, warehouse workers must pay close attention to detail and follow specific procedures to ensure that orders are picked, packed, and shipped correctly.

Advanced technologies such as barcode scanners, automated picking systems, and warehouse management software can be employed to streamline the pick and pack process and minimize the likelihood of errors. By utilizing these technologies and implementing efficient processes, businesses can ensure that their pick and pack operations run smoothly, ultimately leading to increased customer satisfaction and a competitive advantage in the eCommerce market.

In the pick and pack process, each step must be executed with precision and care to ensure that orders are fulfilled accurately and efficiently. The warehouse team is responsible for selecting the correct items from inventory, packing them securely, and shipping them to the customer. This delicate choreography requires meticulous planning, efficient warehouse operations, and the implementation of advanced technologies to guarantee successful order fulfillment.

By understanding and mastering the sequencing of picking, packing, and shipping, businesses can enhance their pick and pack processes and ensure customer satisfaction.

This segment explores different strategies and optimization techniques that can bolster pick and pack fulfillment. By adopting diverse approaches and optimizing warehouse operations, businesses can improve the efficiency and accuracy of their pick and pack processes, ultimately leading to increased customer satisfaction and a competitive edge in the eCommerce market.

There are several strategies that can be employed to ensure effective fulfillment in picking and packing, such as optimizing warehouse layout, leveraging technology integration, and utilizing advanced picking techniques like batch picking, zone picking, and wave picking.

By adopting these diverse strategies, businesses can improve the efficiency and accuracy of their pick and pack operations, resulting in a more streamlined and impactful fulfillment process.

Innovative methods like warehouse layout optimization and technology integration play a crucial role in enhancing pick and pack fulfillment. Efficient warehouse layouts can facilitate large product volumes for simultaneous loading onto trucks, while advanced technologies like AI, robotics, and warehouse management systems can improve accuracy and speed up the fulfillment process. By employing these ingenious methods, businesses can optimize their pick and pack operations and ensure customer satisfaction.

This section delves into the cost structures and operational management components of pick and pack fulfillment. Understanding the costs associated with pick and pack services is essential for businesses to effectively manage their budgets and ensure the profitability of their eCommerce operations.

By implementing cost-saving mechanisms and scalability, businesses can optimize their pick and pack processes while maintaining cost-effectiveness and operational excellence.

The cost structures of pick and pack services typically comprise:

Pick and pack fees

Storage fees

Setup fees

Intake fees

Account management fees

To remain cost-effective, businesses should carefully assess the costs associated with each service and strategically manage their budgets to accommodate these expenses.

By understanding the cost structures of pick and pack services and making informed decisions about budget allocation, businesses can ensure that their eCommerce operations remain profitable and sustainable.

Achieving efficiency and excellence in pick and pack fulfillment requires the implementation of cost-saving mechanisms and scalability. Strategies such as automation, warehouse layout optimization, and carrier rate negotiation can help minimize shipping costs and improve operational efficiency. Additionally, scalability allows businesses to adjust their operations to accommodate seasonal variations in demand and rapid growth.

Implementing advanced post-purchase optimization software enhances cost-efficiency through automation, significantly decreasing ‘Where Is My Order?’ inquiries thanks to precise order tracking and timely notifications. This shift not only liberates customer service resources but also streamlines the returns procedure, potentially converting returns into exchanges, thereby optimizing operational costs.

By implementing these cost-saving and scalable mechanisms, businesses can optimize their pick and pack services and ensure their eCommerce operations remain efficient and competitive.

WeSupply’s analytics empower eCommerce businesses with detailed order flow insights, crucial for cost management and operational efficiency. By understanding every step of the order journey, companies can make informed decisions, optimizing expenses and streamlining customer interactions.

Realtime order and shipment visibility

Book a quick call with our experts to see how WeSupply can help you take control of your shipping experience and stay ahead of the competition. Get real-time data on orders and deliveries from over 1000 carriers so that you can anticipate problems before they occur.

This section addresses the challenges within the pick and pack domain and explores potential solutions. By anticipating potential obstacles and implementing effective strategies to address them, businesses can ensure that their pick and pack operations run smoothly and successfully, ultimately leading to increased customer satisfaction and a competitive edge in the eCommerce market.

Potential obstacles in pick and pack fulfillment include inventory mishaps and operational bottlenecks. By implementing effective inventory management systems and optimizing operations, businesses can minimize these obstacles and ensure that their pick and pack processes run smoothly.

By anticipating and proactively addressing potential hurdles, businesses can preserve customer satisfaction and maintain a competitive edge in the eCommerce market.

Common issues faced in the pick and pack domain include inventory mismanagement, delayed order fulfillment, and operational bottlenecks. By addressing these challenges and implementing solutions such as effective inventory management and warehouse optimization, businesses can ensure that their pick and pack operations run smoothly and efficiently, ultimately leading to increased customer satisfaction and a competitive edge in the eCommerce market.

This section discusses the integration of advanced technology and future-ready approaches in pick and pack fulfillment. By staying ahead of the curve and adopting cutting-edge technologies and innovative strategies, businesses can optimize their pick and pack processes and ensure their continued success in the ever-evolving world of eCommerce.

Advanced technologies such as robotics, augmented reality, and 3D printing offer a range of advantages to pick and pack services, including improved operational efficiency, reduced chances of mistakes, and increased productivity. By incorporating these cutting-edge technologies into their pick and pack processes, businesses can enhance their services and stay ahead of the competition in the rapidly evolving eCommerce market.

Automation, AI, and data-driven decisions play a crucial role in optimizing pick and pack fulfillment processes. By leveraging these future-forward strategies, businesses can increase accuracy, speed up the fulfillment process, and minimize errors in their pick and pack operations.

By staying ahead of industry trends and adopting innovative approaches, eCommerce businesses can ensure their continued success in the ever-evolving world of online retail.

WeSupply emerges as a key player in the post-purchase arena, enhancing the overall shopping journey with capabilities such as instantaneous order tracking, reliable delivery estimates, and a broad connection with various WMS solutions and international shipping carriers. Furthermore, its comprehensive analytics delve into the complex world of logistics, delivery, and order oversight, offering businesses the clarity needed to enact informed strategies. This intelligence enables companies to streamline every facet of the process from the moment an order is initiated to its final reception, guaranteeing a continuous level of customer satisfaction.

This section explores the advantages and potential challenges of outsourcing pick and pack services, particularly when entrusting order fulfillment to a third-party logistics (3PL) provider. By weighing the benefits and drawbacks of outsourcing, businesses can make informed decisions about whether to handle their pick and pack operations internally or partner with an external provider.

Outsourcing pick and pack services can offer businesses cost-savings, increased productivity, and the option to forgo the burden of sustaining warehouse space. However, outsourcing also comes with potential challenges, such as a lack of control over the process and potential difficulties with communication between the outsourcing partner.

By carefully evaluating the pros and cons of outsourcing pick and pack services, businesses can determine the best approach for their specific needs and goals.

When outsourcing pick and pack services, it is important to ensure seamless operations through expertise, resource management, and addressing potential challenges. By partnering with a 3PL provider that offers the necessary expertise and resources, businesses can optimize their pick and pack processes and overcome potential obstacles.

By addressing potential challenges and ensuring seamless operations, businesses can maintain a competitive edge in the eCommerce market and guarantee customer satisfaction.

This section discusses the process of selecting and working in collaboration with a pick and pack partner for eCommerce businesses. By assessing factors such as location, pricing, and services offered, businesses can choose the right partner to meet their specific needs and goals.

Through effective collaboration, businesses can optimize their pick and pack operations and ensure continued success in the competitive world of eCommerce.

When selecting a pick and pack partner, it is crucial to consider factors such as location, pricing, and services offered. By assessing these factors, businesses can find a partner that aligns with their specific needs and goals.

Additionally, effective collaboration with a pick and pack partner can help optimize operations, ensuring that orders are fulfilled accurately and efficiently, ultimately leading to increased customer satisfaction and success in the eCommerce market.

This section looks ahead to the future of pick and pack fulfillment, anticipating emerging trends and advancements in the domain. By staying informed of industry trends and innovations, businesses can adapt to the ever-evolving landscape of eCommerce and ensure continued success in the competitive world of online retail.

By anticipating and preparing for future trends and developments in the pick and pack domain, businesses can stay ahead of the curve and remain competitive in the rapidly evolving world of eCommerce. Strategies such as investing in automation, providing training for staff on the latest technologies, and remaining apprised of industry news can help businesses prepare for the upcoming trends and advancements in the pick and pack domain.

By staying informed and adapting to changing trends, businesses can ensure their continued success in the competitive world of online retail.

In conclusion, pick and pack fulfillment is a fundamental aspect of eCommerce order fulfillment, playing a crucial role in ensuring customer satisfaction and overall success. By optimizing warehouse management, implementing advanced technologies, and employing innovative strategies, businesses can enhance their pick and pack processes and maintain a competitive edge in the ever-evolving world of eCommerce.

Looking ahead to the future of pick and pack fulfillment, it is crucial for businesses to stay updated on industry trends and advancements. This ensures they are well-equipped to navigate the challenges and opportunities that lie ahead.

While Pick and Pack Fulfillment is integral to the mechanics of eCommerce, the adoption of post-purchase enhancement solutions like WeSupply can significantly upscale your business operations. WeSupply offers an effortless interface for live tracking of orders and shipments, timely notifications of order progress, predictions of delivery dates prior to purchase, and integration with a wide range of global carriers. This all-encompassing approach enriches customer interactions and satisfaction throughout the entirety of their purchasing experience.

In this blog post, we have explored the intricacies of pick and pack fulfillment in eCommerce, discussing:

Its importance

Various strategies and optimization techniques

Challenges faced

Future trends

The key takeaways include:

Understanding the critical role of pick and pack in order fulfillment

Optimizing warehouse management and order processing

Staying ahead of industry trends and advancements

By implementing these strategies and insights, businesses can ensure their continued success in the competitive world of online retail.

As the eCommerce landscape continues to evolve, businesses must remain agile and adaptive in their approach to pick and pack fulfillment. By optimizing their processes, leveraging advanced technologies, and staying informed of industry trends, businesses can ensure customer satisfaction and overall success in the competitive world of online retail.

The future of pick and pack fulfillment is undoubtedly bright, and through effective implementation and continuous improvement, businesses can uphold their excellence in eCommerce.

In summary, pick and pack fulfillment is a critical aspect of eCommerce order fulfillment, playing a crucial role in ensuring customer satisfaction and overall success. By optimizing warehouse management, implementing advanced technologies, and employing innovative strategies, businesses can enhance their pick and pack processes and maintain a competitive edge in the ever-evolving world of eCommerce. As we look forward to the future of pick and pack fulfillment, it is essential for businesses to stay informed of industry trends and advancements, ensuring that they are well-equipped to navigate the challenges and opportunities that lie ahead.

The pick and pack process involves collecting items from the inventory and packing them for shipment, which is an important part of the order fulfillment process and needs to be done with high efficiency.

Pickers locate and select products for each order, then pass it off to the next zone. The order will move through all relevant zones before going to the packing station for final packing and shipment.

Order fulfillment options typically include in-house, using a third-party logistics provider (3PL) and dropshipping. Each option offers different advantages and is better suited to different types of ecommerce stores, depending on shipping volumes, customer location, and team strengths. Additionally, a hybrid model combining two or more of these order fulfillment solutions is also an option.

In the realm of enhancing operational efficiency, advanced post-purchase optimization software such as WeSupply emerges as a game-changer. By automating crucial aspects of the customer journey, such technology significantly reduces the volume of ‘Where Is My Order?’ inquiries, courtesy of its precise order tracking.

Businesses can optimize their warehouse layout by utilizing storage systems, software, and picking strategies for improved efficiency.

Potential challenges in pick and pack fulfillment include inventory mishaps and operational bottlenecks, which can be addressed through effective inventory management systems and optimizing operations.

Learn How To Create Successful Post Purchase Email Campaigns

Build an effective post-purchase email flow that helps you increase customer satisfaction and drive revenue growth!

In this comprehensive guide, we’ll delve into the concept of cross-docking and explore its history, benefits, challenges, and best practices.

Discover how safety stock can transform your retail business and prepare you for the future of customer-centric inventory management.

Join us as we explore the what, why, and how of the shift towards carbon neutral shipping in the world of logistics.

In this post, we’ll dive into the world of 4PL logistics, its benefits, challenges, and how it compares to more traditional logistics models.

This article offers a detailed comparison of standard and expedited shipping in e-commerce, helping you make informed logistics choices.

As we dive into the intricacies of inbound logistics, we will explore its challenges, as well as best practices for optimizing its processes.

In this blog post, we’ll explore the ins and outs of SFP, including eligibility requirements, advantages, and strategies for success.

Read on to discover the world of pick lists, their components, and how they contribute to the smooth operation of warehouses.

This blog post explores outbound logistics in e-commerce, its challenges, and optimization best practices.